AECO

Efficiency up to 120 kg/h

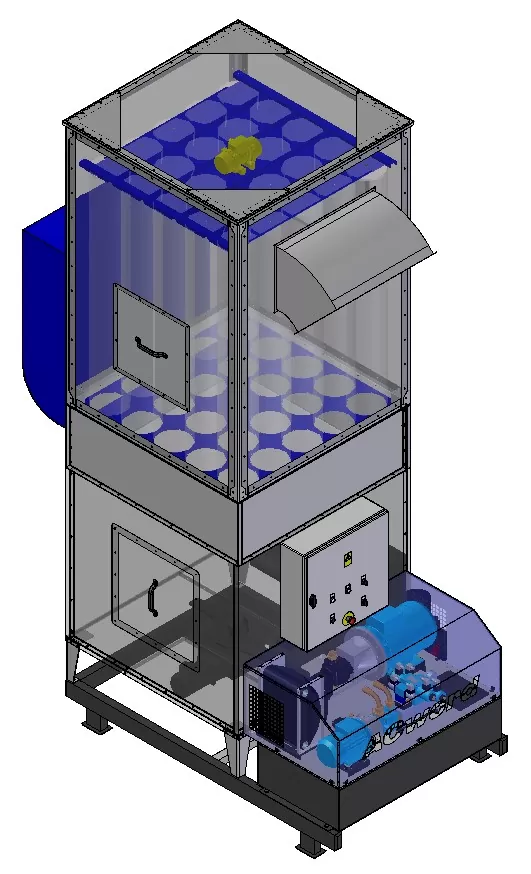

The AECO range of hydraulic briquette presses is designed primarily for application in small or medium-sized joiner workshops. The briquette press serves the purpose of processing wood waste with a moisture content of 8-15% in order to produce briquettes (fuel) from sawdust, wood shavings and wood dust, using a hydraulic piston mechanism. The briquetting process reduces the volume of waste material by up to 90%. The benefits are savings in the storage area, the creation of a dust-free environment and easy transportation, all of which is achieved without bonding material.

Fuel efficiency of 1 kilogram of briquettes: 15 – 18 MJ/kg

The feeding hopper is designed for setup with filtration superstructures and a ventilator. This comprehensive, unmanned system of wood dust extraction from the machinery directly to the briquette press provides maximum convenience in the processing of your waste.

Material types suitable for briquetting

- sawdust, wood shavings

- wood and paper dust

- milled paper

- milled biomass

- chaff, straw

- waste from impregnated material – DTM, MDF

Advantages and hallmarks of the AECO briquetting presses

- High briquette quality – provides a high quality of combustion (low briquette residue) and maximum possible fuel efficiency

- Resistance to failure combined with a long operating life – application of high-quality materials for the manufacturing of the press mechanism, its robust design, as well as modern technology and high-precision machining

- Ease of operation – the entire process of briquetting is controlled by a computer

- Inspection and maintenance – oil level reader and a counter of the machine hours are standard features of AECO presses

- Low operation cost – low-consumption motors reduce the electricity costs to a minimum

- Hopper – designed for use together with a filtration superstructure and a ventilator for the direct transport of waste to the briquetting press

- Hopper inspection door – for inspection and easy access to the hopper body

- Left- or right-side mount – upon the customer’s request, we offer positioning of the press mechanism to accommodate the unit for a left- or right-side mount

- Outdoor operation – when supplied with special oil, AECO briquetting presses are capable of operation outdoors at temperatures as low as -25 °C

- Low level sensor – this feature turns the press off automatically once the level of the material in the hopper is too low. After material is resupplied, the press resumes operation automatically

Standard equipment

- electrical switchboard with a control computer for unmanned operation of the press

- automatic regulation of the length and quality of briquettes

- piping system for transporting briquettes to the packing site – 2 arches to a height of 1,200 mm

- thermostat for oil temperature control

- pressure gauge for working cycle control

- level mark of the hydraulic oil tank

- screw feeder of material to the pressing chamber

- extracting cutter on the hopper bottom

- sensor of the material level in the hopper for automatically turning the press on and off

- emergency entrance port on the hopper wall

- operation hours counter

- oil cooler or preparation for its installation

| Press capacity [kg/h] | 20-40* |

| Briquett diameter [mm] | 65 |

| Power input [kW] | 4,4 |

| Weight [kg] | 880 |

| Hopper volume [m³] | 1,7 |

| Oil cooling system | Optional |

| Filtration superstructures | Optional |

| Height [mm] | 1556 |

| Width [mm] | 1542 |

| Length [mm] | 1967 |

| Press capacity [kg/h] | 40-60* |

| Briquett diameter [mm] | 65 |

| Power input [kW] | 5,4 |

| Weight [kg] | 890 |

| Hopper volume [m³] | 1,7 |

| Oil cooling system | Optional |

| Filtration superstructures | Optional |

| Height [mm] | 1556 |

| Width [mm] | 1542 |

| Length [mm] | 1967 |

| Press capacity [kg/h] | 50-80* |

| Briquett diameter [mm] | 65 |

| Power input [kW] | 6,9 |

| Weight [kg] | 945 |

| Hopper volume [m³] | 1,7 |

| Oil cooling system | Optional |

| Filtration superstructures | Optional |

| Height [mm] | 1556 |

| Width [mm] | 1542 |

| Length [mm] | 1967 |

| Press capacity [kg/h] | 90-120* |

| Briquett diameter [mm] | 65 |

| Power input [kW] | 9,3 |

| Weight [kg] | 1205 |

| Hopper volume [m³] | 1,7 |

| Oil cooling system | Optional |

| ltration superstructures | Optional |

| Height [mm] | 1556 |

| Width [mm] | 1542 |

| Length [mm] | 1967 |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472