Pallet Nailing Machines

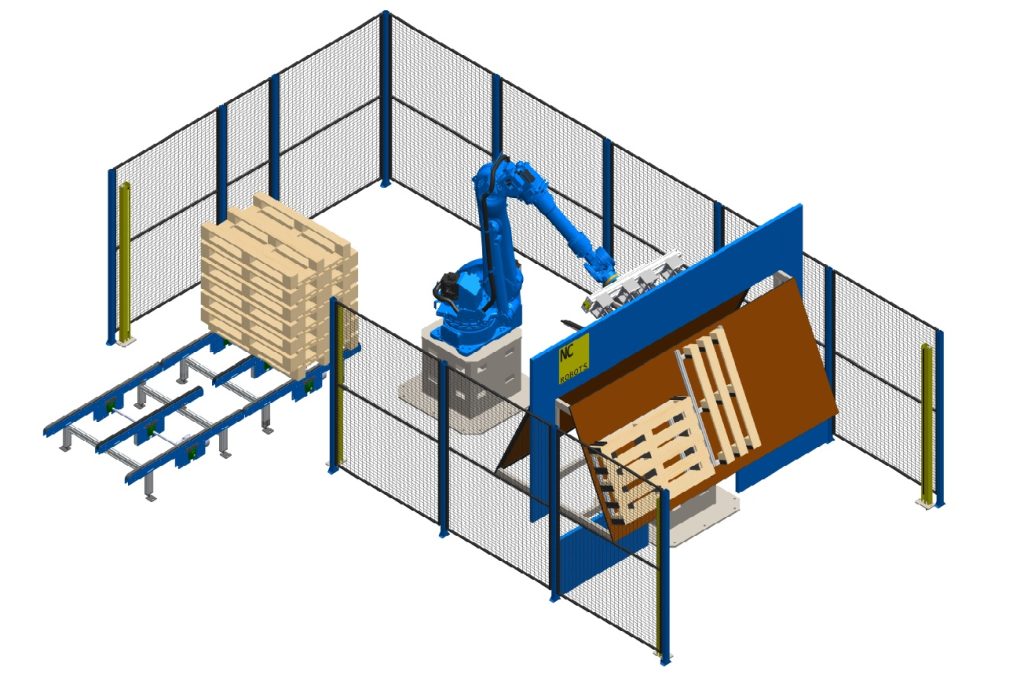

NC Robots – Pallet Nailing Robot

NC Robots – pallet nailing robot with a rotary table is the ultimate solution for businesses looking to increase their pallet production efficiency while reducing labor costs. With this innovative machine, you can achieve up to 600 pallets in an 8 hour shift with only 2 operators.

Read more

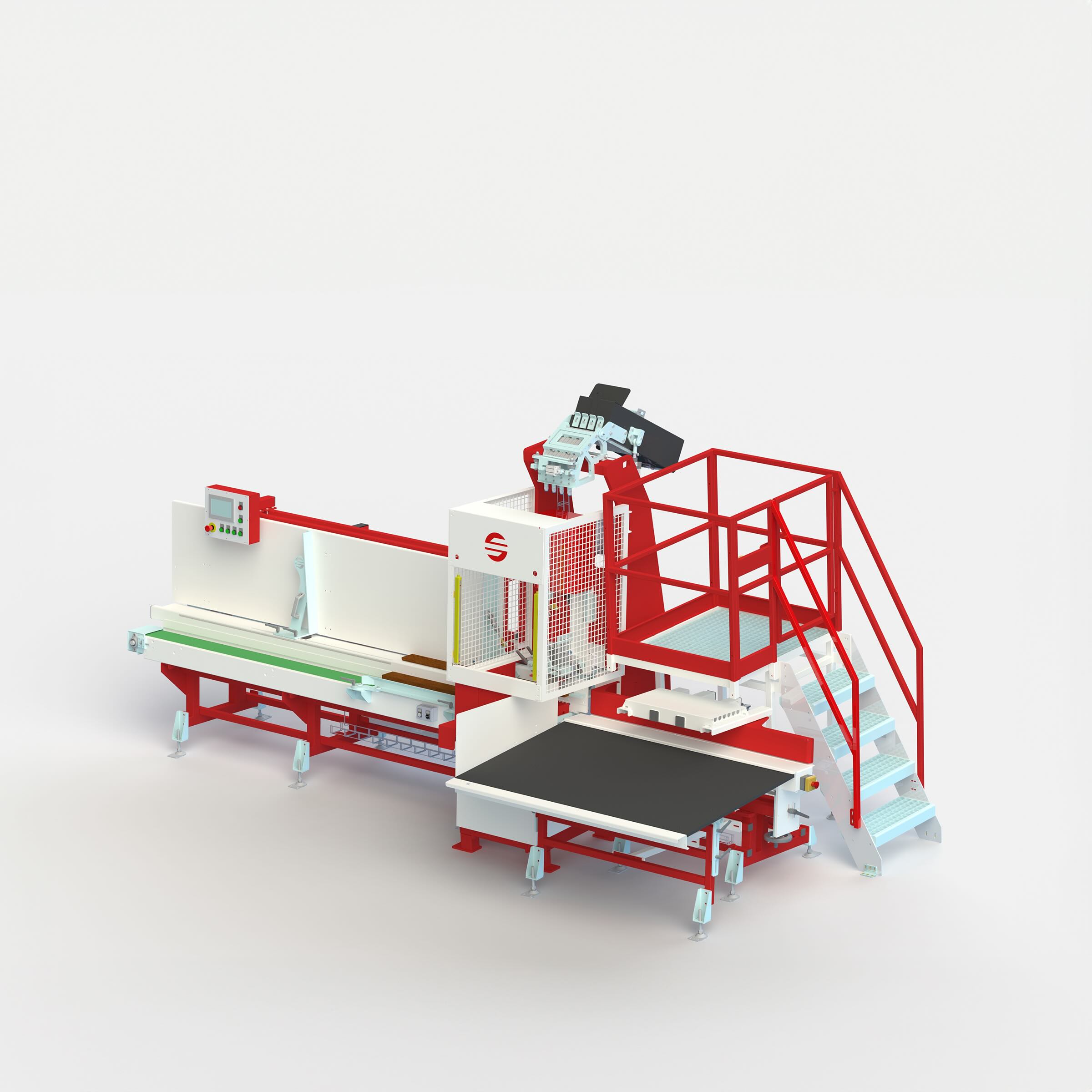

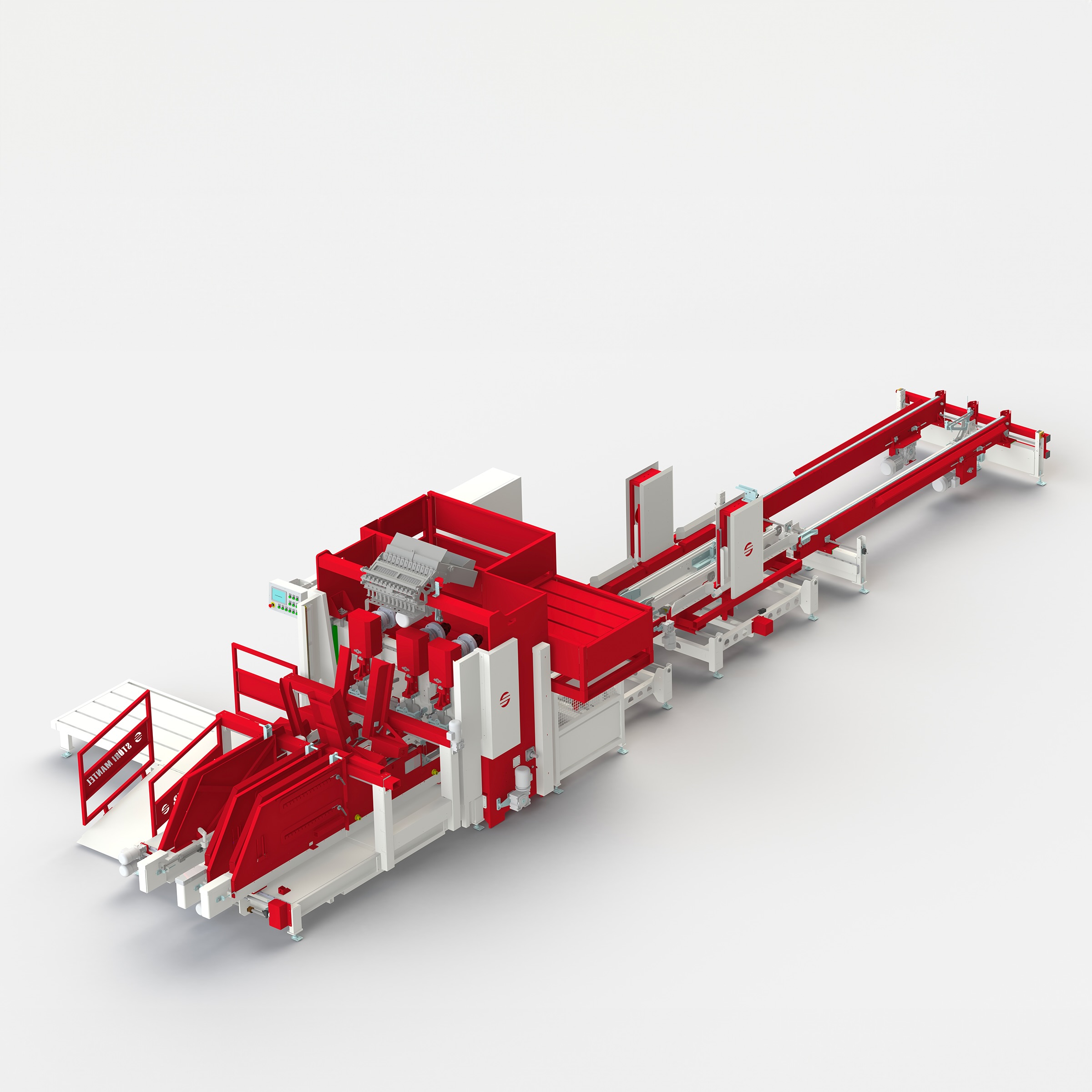

Störi Mantel – Leg Machine

The Störi Mantel Leg Machine is an automatic device for producing the bottom parts of wooden pallets, also known as pallet bases or legs, which operates on the proven principle of electromechanical nailing.

Read more

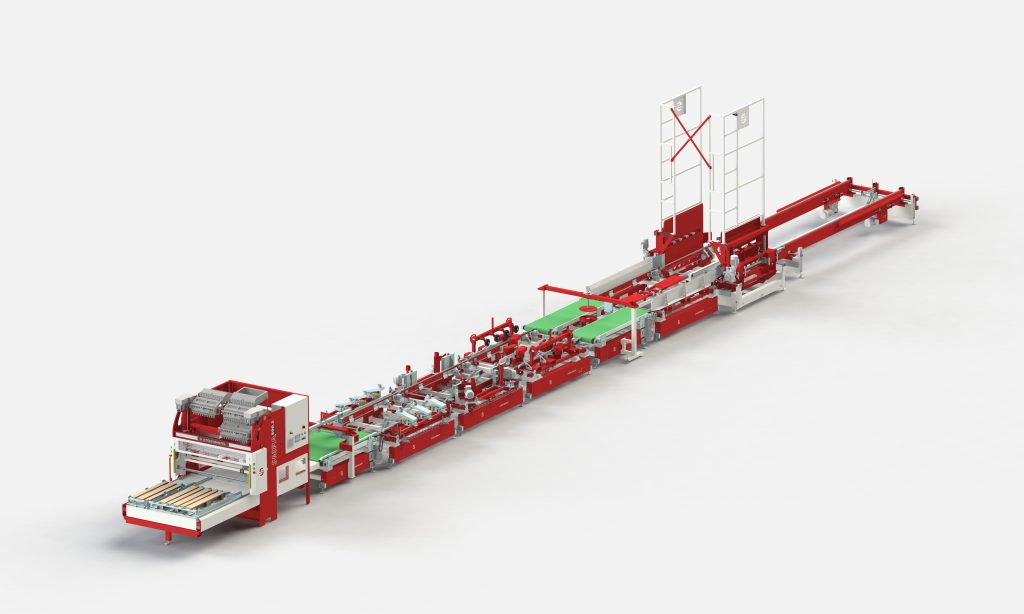

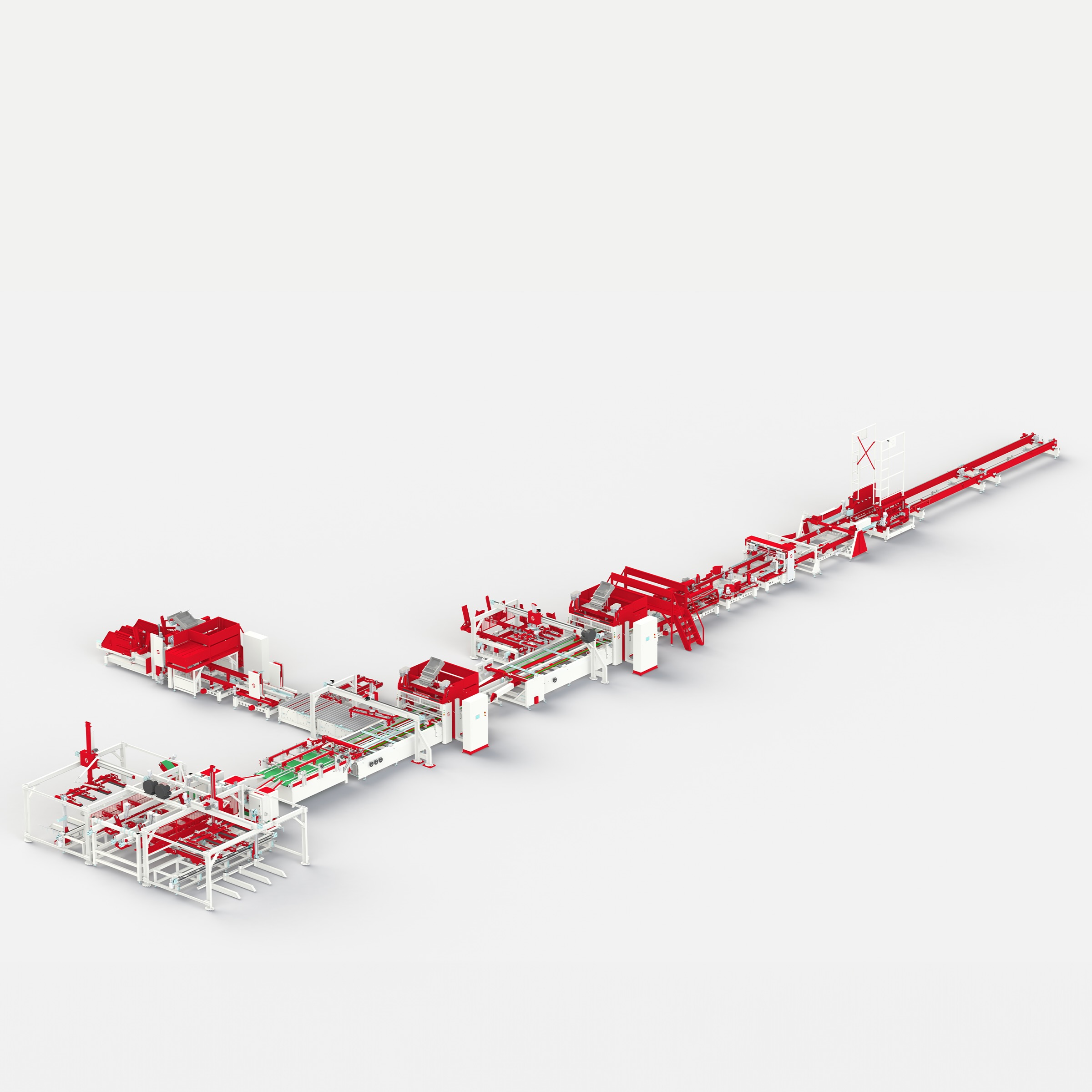

Störi Mantel – Standard

The Standard Nailing and Processing Line is a reliable and cost-effective solution for manufacturing a variety of pallet types. With a production capacity of 1-2 pallets per minute, this line is ideal for businesses seeking to balance efficiency and affordability in their pallet production processes. Standard Nailing Line: Efficient, Adaptable, and Cost-Effective Pallet Production The Standard Nailing Line is available in four foundation table sizes: 1500 mm, 2000 mm, 2500 mm, and 3000 mm. These dimensions determine the maximum pallet length the line can handle, making it adaptable to various production needs. Designed for efficiency, this line requires only two operators, ensuring reduced labor costs and smooth operation. Effortless Pallet Production With Störi Mantel palletizing lines, you can easily manufacture the most common and even atypical pallets. Thanks to the universal/fixed template, manual reconfiguration is simple and quick, allowing for seamless transitions between different pallet types. The nailing precision, accurate to +/- 1 mm, ensures consistent, high-quality results for every pallet. Reduce Costs with the Patented Electric Nailing System The electromechanical nailing drive is the most energy-efficient system in its class, consuming just 1.2 kWh per 100 pallets. Unlike hydraulic systems, this innovative technology eliminates the need for oil refills, maintenance, and disposal, significantly lowering operational costs while reducing noise. Invest at Your Own Pace If purchasing the entire line upfront isn’t feasible, the Standard Line offers a modular design. You can start with the most critical components and expand the system incrementally as your production needs grow. Customizable for Any Space The Standard Line is highly versatile, with configurations available in “I,” “L,” or “U” shapes to fit your facility layout. By providing your workspace dimensions in advance, we can design a setup tailored to your specific requirements. Save on Material Costs Störi Mantel’s nailing machines work with freely poured nails of various types, including EPAL nails, eliminating the need for expensive collated nails. Suitable nail lengths range from 27 mm to 90 mm, offering flexibility while keeping material costs low. Why Choose the Standard Nailing Line? Four size options for diverse production requirements. Energy-efficient technology for cost savings. User-friendly design, requiring only two workers. Precision engineering for consistent quality. Scalable investment options to suit your budget. Transform your pallet production today. Contact us to learn more about how the Standard Nailing Line can elevate your operations.

Read more

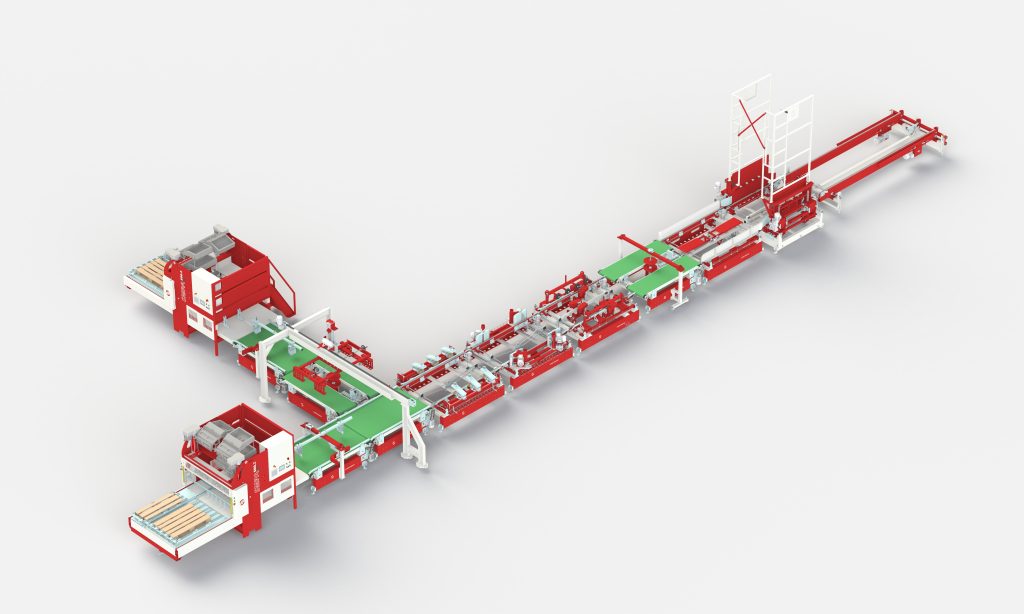

Störi Mantel – Standard Dual Line

The Standard Dual Pallet Nailing Line and Processing Line is a reliable solution for businesses requiring efficient pallet production. Designed to handle a variety of pallet types, this system can produce up to 3 pallets per minute, ensuring high productivity for medium to large-scale operations. This advanced line retains all the features of the Standard Line while incorporating two SMPA500.2 ED nailing machines. With dual nailing capabilities, the system delivers enhanced efficiency and precision, making it ideal for businesses looking to optimize their production process.

Read more

Störi Mantel – Universal Pallet Nailing Line

The universal high-capacity pallet nailing line is designed for efficient and precise pallet production in three operations across three nailing machines. One of the machines fully assembles the pallet lids, ensuring seamless workflow and consistency. Ideal for companies specializing in large-scale pallet manufacturing, this line enables fast daily changeoversto different pallet types and sizes, maximizing productivity and flexibility.

Read more

Störi Mantel – Tandem

The high-capacity Störi Mantel Tandem pallet nailing line produces pallets in two operations using two tandem-arranged nailing machines. Ideal for large-scale pallet production, this system is designed for continuous output, where frequent reconfiguration for different pallet types or sizes is not a priority.

Read more

Störi Mantel – DYNAMIC 1

The Störi Mantel Dynamic 1 DM1 pallet nailing line is built for fast two-way pallet production, with the flexibility to handle pallet lids. It delivers 6-9 pallets per minute, ensuring high-speed efficiency.

Read more

Störi Mantel – DYNAMIC 2 Pallet Nailing Line

The Störi Mantel DYNAMIC 2 DM2 line is designed for the high-speed production of two-way dual-operation pallets. With its remarkable efficiency, it can produce between 6 and 9 pallets per minute.

Read more

Störi Mantel – DYNAMIC 3

The Störi Mantel DYNAMIC 3 DM3 pallet nailing line is primarily designed for the production of pallet lids, but with the right configuration, it can also produce two-way pallets. Its key advantage is its speed, capable of producing 6 to 9 lids per minute.

Read moreReliable Pallet Machinery for Manufacturing & Recycling

CIBOR Woodworking Machinery Ltd. is a leading UK supplier of cutting-edge solutions for the pallet manufacturing and pallet recycling industries. Our extensive product lineup includes the latest in pallet production lines, pallet nailing lines, pallet dismantle saws, and pallet stripping machines, all designed to improve efficiency, accuracy, and profitability for operations of every size.

Pallet Nailing Line – Smart Solution in Pallet Production

High-performance Pallet Nailing Machine from our offer is a game-changer in modern pallet production. Designed for speed and precision, this robust system is engineered to meet the growing demands of both small manufacturers and high-capacity industrial plants.

Our different Pallet Nailing Lines are engineered to meet a wide range of production requirements, regardless of your desired output capacity, available floor space, or number of operators. Whether you’re running a small-scale workshop or a high-volume industrial facility, we offer flexible and fully customizable solutions to match your business needs.

Key benefits include:

-

Scalable Capacity – From low to high output lines, tailored to your production goals

-

Labor Optimization – Options for manual, semi-automatic, or fully automated operation based on available workforce

-

Modular Design – Easily expandable as your business grows

-

Precision & Speed – Ensures consistent nail placement and fast cycle times

-

Durable Build & Low Downtime – Made with premium materials for long-term, heavy-duty use, and ease of maintenance

-

Automation: Automated nailing ensures consistent assembly with minimal error

-

Customizable Design: Supports various pallet sizes and configurations

-

User-Friendly Interface: Easy to operate with minimal training

-

Cost-Effective: Reduces labor time and material waste for a faster ROI

Whether you need a standard solution or a pallet nailing robot, we have scalable options tailored to your exact needs.

Complete Pallet Production Line Solutions

CIBOR Woodworking Machinery offers fully integrated pallet production lines, designed to handle every step of the pallet-making process. From sawing and nailing to stacking and finishing, our solutions include:

-

Pallet Nailing Line – with modular design, scalable capacity, targeting labor optimization

-

Pallet Blocks Saw for precision component cutting

-

Custom configurations to suit unique production workflows

Our pallet production machinery increases throughput, reduces downtime, and helps you maintain consistent quality at scale.

Pallet Recycling & Dismantling Equipment

Supporting sustainability and cost reduction, CIBOR Woodworking Machinery also supplies a range of machines for pallet recycling, including:

-

Pallet Dismantle Saws – Ideal for reclaiming usable timber

-

Pallet Stripping Machines – Efficiently separate boards for reuse

-

Pallet Band Saws – Designed for precision and durability

Whether you’re reclaiming pallets or preparing them for resale, our equipment helps maximize material recovery while minimizing labor.

Why Choose CIBOR Woodworking Machinery?

-

Complete Solutions for pallet manufacturing and recycling

-

Scalable machinery for small workshops to large-scale operations

-

Expert technical support and comprehensive after-sales service

-

High-efficiency systems built for long-term performance

-

Flexible financing options through our partnership with Venture Asset Finance

Ready to Upgrade Your Pallet Operations?

Invest in advanced pallet production line technology from CIBOR Woodworking Machinery Ltd. and elevate your manufacturing or recycling capabilities. Whether you’re building new pallets or recovering old ones, our machines deliver unmatched efficiency, accuracy, and reliability.

We work with 30 suppliers

How can we help you?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472