SPL- 9.1C PUR glue applicator

Automatic single-component glue applying machine.

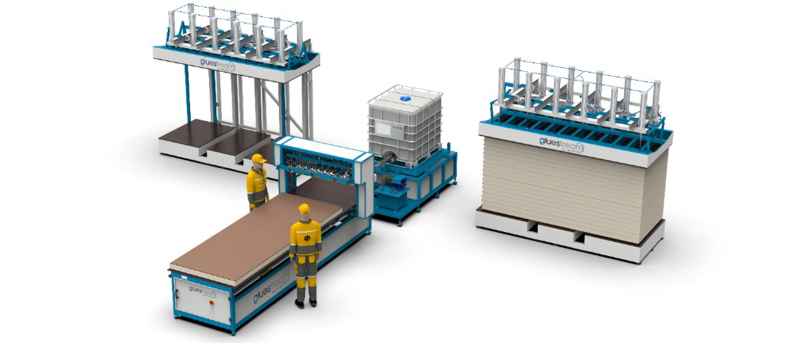

We are excited to present the Gluestream SPL-9.1C.PUR, an innovative and automated single-component PUR (1-C PUR) glue-applying machine specifically designed for the manufacturing of a variety of sandwich panels. Thanks to its versatile design, the SPL-9 can be employed on either a stationary platform or a movable platform, featuring options for both manual and electric drive systems.

Why Choose 1-C PUR Technology?

You may wonder what sets 1-C PUR technology apart. This humidity-reactive adhesive boasts exceptional bonding properties, making it an ideal solution for a range of materials, including plastics, metals, aluminium, OSB, MGO, plywood, fiberglass, fibre cement boards, plasterboards, EPS, XPS, PIR, PUR boards, stone wool, wood wool, and many others. Notably, this type of adhesive is extensively used in SIPs manufacturing and can be tailored for fully automated SIPs production lines.

The Rise of Structured Insulated Panels (SIPS)

The technology behind structured insulated panels (SIPS) manufacturing is gaining significant traction in the construction sector. At Gluestream, we develop machinery and technology that caters to various levels of investment. Consequently, each company can initiate SIPs manufacturing with a cost-effective SIP production set of equipment.

Customisable Machine Parameters

All machine parameters can be tailored to meet the specific requirements of our customers during the order consideration stage. The glue-applying machine SPL-9 is a vital component of the SIPs technological process and can be seamlessly integrated with SIPs processing machinery, SIP cutting machinery, and SIPs grooves-making machinery.

Efficiency and Compatibility

Remarkably, one SPL-9 machine can serve up to six Gluestream Pneumatic Presses. The SPL-9 is compatible with one or two C-type presses and can efficiently operate with up to six SIPs presses simultaneously. With a maximum output that is only constrained by the technological process, this glue-applying machine ensures optimal application properties throughout the production run.

Key operational parameters include:

- Open Joint Time: The duration the adhesive is exposed to air before the pressing force is applied.

- Pressing Time: The time the material remains in the press.

For further insights, please follow the link to discover how the manufacturing capacity of machinery is calculated in the context of structured insulated panels (SIPS) manufacturing technology.

Multiple Modifications Available

The SPL-9 is available in several modifications, including:

- Stationary platform

- Manually movable machine on polyamide wheels

- Platform installed on rails

Additionally, we offer various operation table modifications:

- Stationary table covered with specialised plywood or stainless steel

- Passive roller conveyor

- Driven roller or belt conveyor

The footprint of the standard modification of the SPL-9 1-C PUR machine features a stationary platform with a glue-applying area of 1250 x 3000 mm.

Tailored Solutions for Your Production Needs

Please share your requirements with us, and we will assist you in selecting the ideal glue application system for sandwich panel production, tailored to the specifics of your manufacturing process, final product, and objectives.

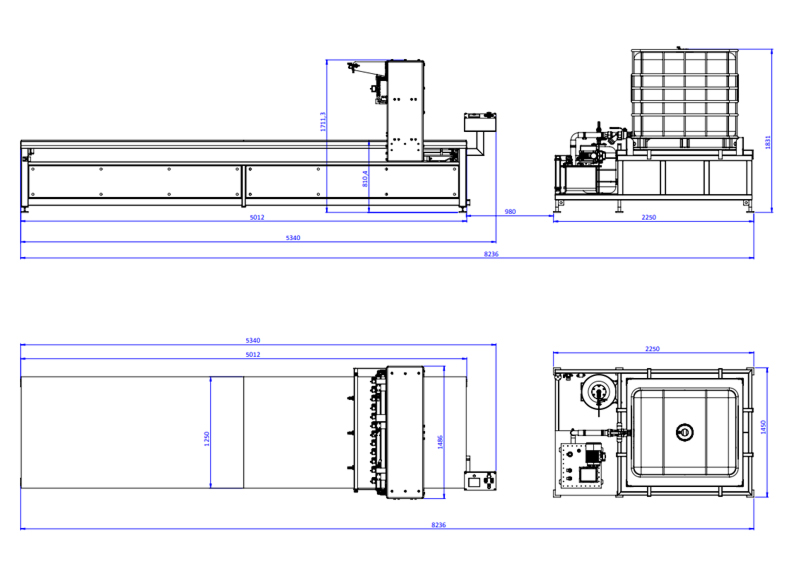

Specifications of the Standard Modification of the SPL-9 1-C PUR Adhesive Application Machine

All Gluestream machinery is equipped with a remote access module, providing customers with 24/7 online internet support. Should you require technical assistance, do not hesitate to contact us. Our team possesses extensive experience in adhesive technology, acquired over many years, and is eager to share our knowledge with you.

In summary, the Gluestream SPL-9.1C.PUR stands out as the premier choice for those seeking a reliable sip panel glue machine and PU glue applicator, ensuring efficiency and excellence in every application.

| Type of glue | 1-C Polyurethane |

|---|---|

| Viscosity | 2000-30000 mPs |

| Glue consumption | 100-150 g/m2 |

| Glue applying accuracy | +/- 5 g/m2 |

| Distance between glue lines | 10 mm |

| Glue applying width | 1250 mm |

| Glue applying lenght | 3000 mm |

| Glue applying height | 300 mm |

| Speed of glue application | up to 25 m/min |

| Air supply | 6-8 bar |

| Air consumption per cycle | 5 nL |

| Power supply | 3 phase, 400V, 50 Hz |

| Power consumption | up to 5 kW |

| Weight | 1500 kg |

| Lenght | 5500 mm |

| Width | 1500 mm |

| Height | 1700 mm |

| Personel | 2 |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472