TEKNO BASIC

CNC Milling Hinge Boring Machine

The TEKNO BASIC is a CNC milling – hinge boring machine with 3 controlled and interpolated axes, driven by brushless motors.

It is a multifunctional, fast and compact machine, suitable for joineries thanks to its versatility.

It can be set up in 3 different modes: milling – anuba hinge inserting unit, milling unit only, anuba hinge inserting group only.

Milling – 3 Controlled Axis Hinge Boring Machine

The TEKNO BASIC machine is suitable for door, frame and panel working.

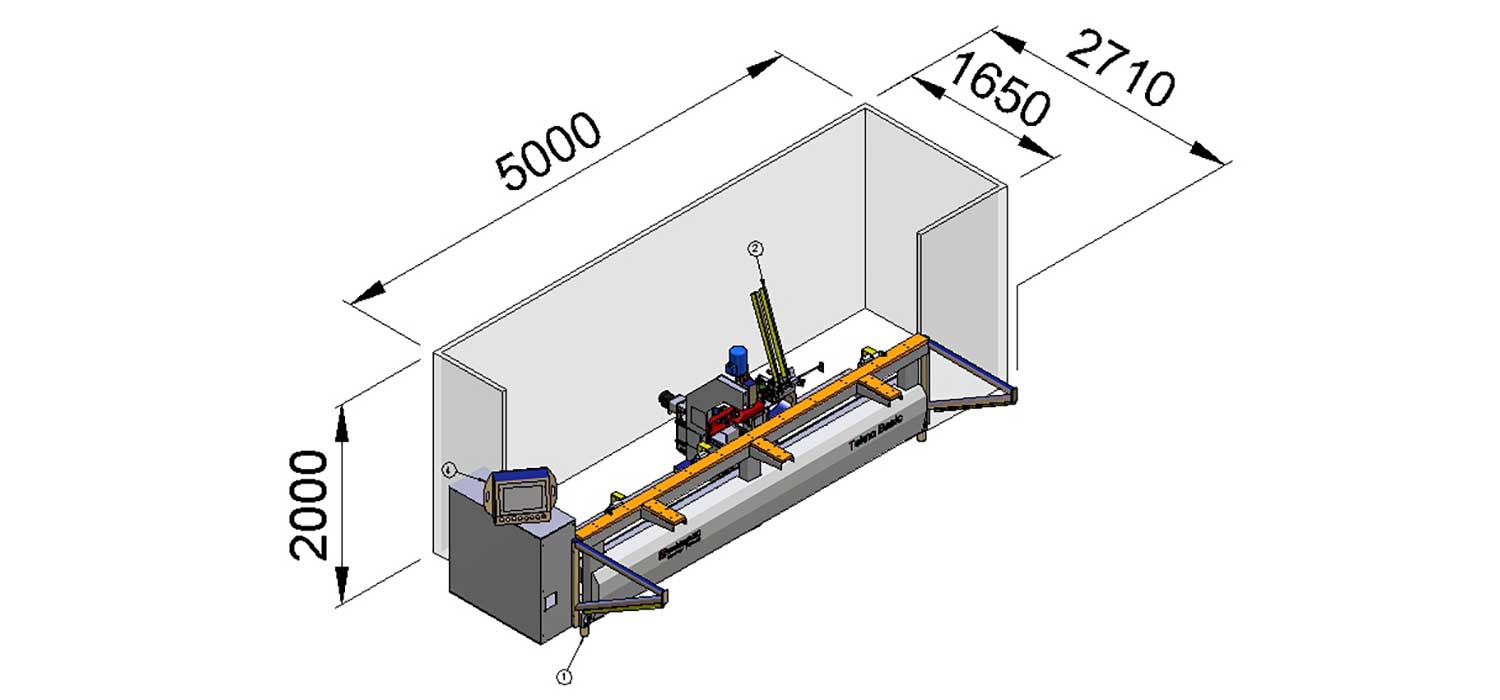

The 3100 mm worktable allows working very long pieces.

The milling and anuba heads are automatically placed according to the values set on the working program.

The anuba hinge unit is equipped with a double storage for male and female anuba hinges. The machine will choose from which storage to extract the anuba hinges, according to the settings entered in the program.

Advantages in CNC woodworking

- Multifunctional machine

- Programming through pre-set macros

- Remote technical support

- Machine body internal manufacturing

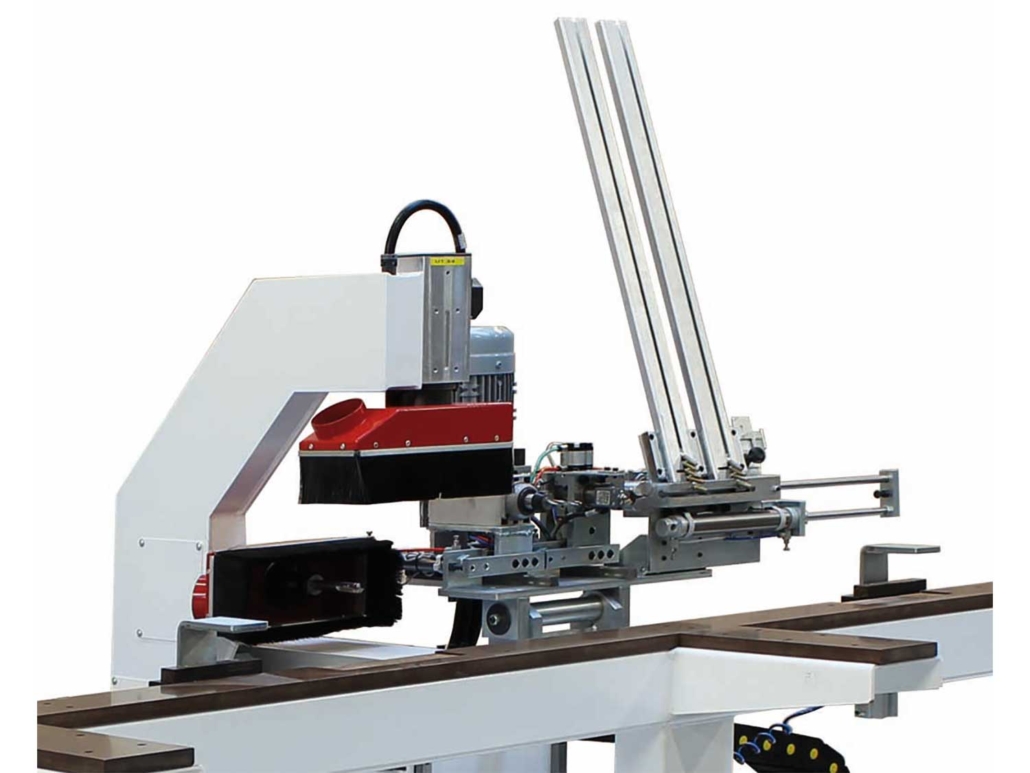

Anuba Hinge Unit

The anuba hinge unit, with automatic positioning, is equipped with an electro-spindle, for drilling operations, and a screwing motor for inserting the simple anuba hinge.

The unit is also equipped with a double storage for male and female anuba hinges, with an automatic loader. The machine will choose from which storage to extract the anuba hinges, according to the settings entered in the program.

Electro-spindles

The machine is equipped with electro-spindles for drilling and milling operations, both horizontal and vertical.

A further version of the Tekno Basic machine features 2 horizontal milling units (one for rough, the other for finish) with separate tool lodging.

Easy and Intuitive Software

Any work management is simple and functional thanks to pre-set macros.

The user-friendly software allows multiple programming functions and the possibility of using joblists to call up a list of jobs.

CNC Software

- Programming system through pre-set macros.

- 15″ colour touch screen monitor.

- Recipe storage.

- Ethernet port for network connection.

- USB port.

Remote Assistance

With a remote connection to your CNC software, Metalstar team ensures the best step-by-step assistance ever for all your needs.

| Data | Value |

|---|---|

| X-axis working stroke | 3100 mm |

| Y-axis working stroke | 400 mm |

| Z-axis working stroke | 190 mm |

| X-y-z-axes’ maximum movement speed | 60/15/15 m/min |

| Controlled axes | 3 |

| Weight | 1000 kg |

| Overall dimensions with fences | 5200 x 2710 x 2000H mm |

| Data | Value |

|---|---|

| Anuba hinge head tilting | -5° +45° |

| Electro-spindle for anuba hinge drilling | 12000 rpm |

| Single anuba hinge screwing device | standard-type |

| Double anuba hinge screwing device | optional |

| Bit for anuba hinge hole | standard-type |

| Data | Value |

|---|---|

| Vertical electro-spindle | 12000 rpm |

| Horizontal electro-spindle | 12000 rpm |

| Cutters (dia. 16 mm) equipped with collets | standard-type |

| Data | Value |

|---|---|

| Vertical and horizontal electro-spindle power | 1.1 kw |

| Drilling motor power | 0.37 kw |

| X-axis motor power | 5.39 n/m |

| Y-axis motor power | 2.86 n/m |

| Z-axis motor power | 5.39 n/m |

| Windows 7 embedded operating system | Programming system through pre-set macros. |

| Ethernet port for network connection | USB port |

| 15″ colour touch screen |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472