TEKNO X2

CNC Milling Hinge Boring Machine

CNC milling and hinge boring machine with 5 controlled axes, the TEKNO X2 is a machine particularly suitable for the production of doors and frames on an industrial scale.

The TEKNO X2 machine is suitable for the woodwork of doors and frames for those countries adopting anuba (as Italy) and paumelle hinge systems.

After a simple setting of the woodwork to be performed, the machine will (through the loading and unloading belts) load the door to be processed and then start the milling and/or drilling and/or anuba hinge screwing processes previously set.

The milling and anuba head is automatically placed according to the values set in the program, reducing the time of the machine mechanical setting.

CNC with 5 controlled axes: work island or as a line machine

The TEKNO X2 is designed to ensure maximum flexibility by facilitating the production of custom-made doors and frames, thanks to the anuba hinge system or concealed hinges.

The machine carries out all necessary milling and drilling operations in just one position.

Electro-spindle placement is completely automatic.

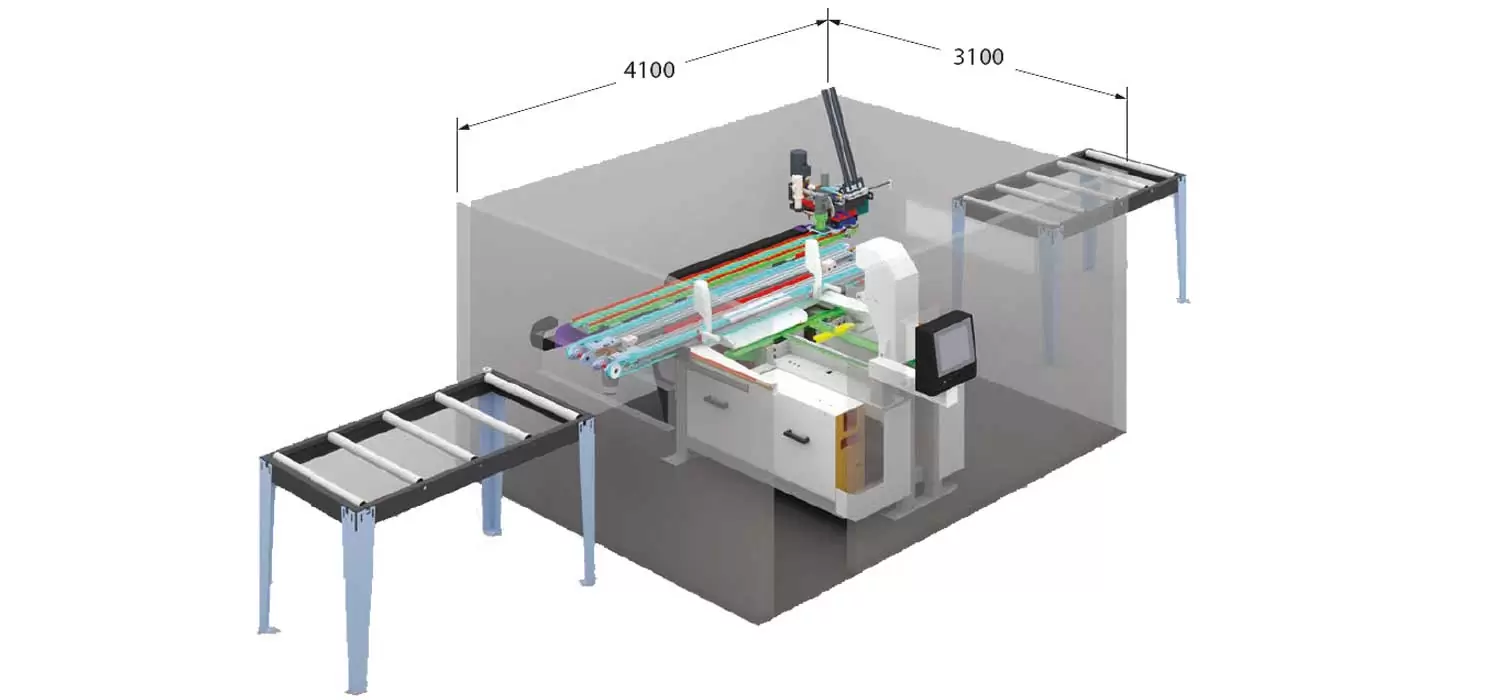

The machine can be set up both as a work island and as a line machine.

Advantages in CNC woodworking

- Work island or line machine

- Production process in less than 2 minutes, with a single positioning

- Colour touch panel

- Pre-set macros for a quick parameter setting

- Remote technical support

- 100% made in Italy

Easy and Intuitive Software

Functional and easy-to-use technology, thanks to pre-set macros that allow any work management.

Multiple programming functions and the possibility of using joblists to call up a list of jobs.

Top-of-the-range Components

High-end components such as linear guides and ball runner blocks, “smart” drives with automatic parameter setting and conditioned control panel.

Air and oil atomisation pressurises and lubricates all moving axes.

Remote Assistance

Metalstar staff will be happy to assist you with all your needs by connecting remotely to your control, so as to provide you with step-by-step assistance.

Production as a Work Island or In-line Machine

The machine can be set up with loading and unloading roller conveyors, either as a work island or as a line machine.

(optional)

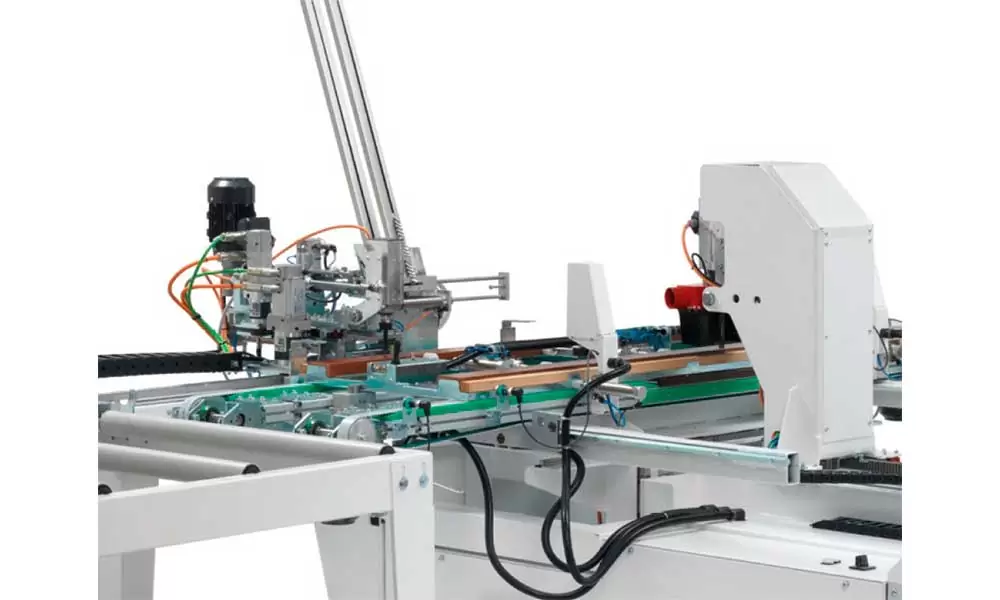

Door Machining: Lock Side

Motor inclination 0° and 90° for machining the lock, key slot and handle hole.

Automated control management.

Equipped with a feeler pin to identify millimetric differences in the width and thickness of the workpiece.

Suction hood equipped with a blower for cleaning the workpiece during the processing phase.

Door Machining: Anuba Hinge and Hinge Side

The working unit with automatic positioning is equipped with an electro-spindle, either for milling or drilling operations according to the tool mounted, and with a screwdriver motor for the simple anuba hinge insertion.

Frame Machining: Flexibility

Increased productivity and efficiency with the new kit for frames’ machining, designed to meet an ever-increasing demand from the market for a product that speeds up setup times while ensuring high levels of finish.

Its hold-down devices block and straighten the parts to be machined and the control manages the entire production cycle, including the choice between concealed or anuba hinges.

| Data | Value |

|---|---|

| Paumelle hinge working area from rh and lh stops | 2500 mm |

| Minimum door width | 550 mm |

| Maximum door width | 1100 mm |

| X-axis working stroke | 600 mm |

| X2-axis working stroke | 2650 mm |

| Y-axis working stroke | 930 mm |

| Z-axis working stroke | 300 mm |

| P-axis working stroke | 140 mm |

| U-axis working stroke | 700 mm |

| Electro-spindles for lock machining | no. 1 |

| Electro-spindle for anuba hinge insertion holes and hinge side milling | no. 1 |

| Gearmotor for anuba hinge screwing dia. 13/14 mm | no. 1 |

| Anuba hinge head tilting | 0°-10° |

| Anuba hinge screwing motor power | 1 hp – 0.75 kw |

| Electro-spindle power for hinge-paumelle hinge seat milling and anuba hinge drilling | 0.5 hp – 0.37 kw |

| Axes driven by brushless motors | x – x2 – y – z – p |

| Lock side milling motor power | 3 hp – 2,2 kw |

| X-x2-y-z-axes’ motors’ power | 2.4 n/m |

| P-axes motors’ power | 1.2 n/m |

| Automatic positioning of milling-anuba hinge head | standard-type |

| Touch screen | 15 inches |

| Loading and unloading belts | standard-type |

| Motorised stretcher to simplify the door lodging | standard-type |

| Automatic centralised lubrication of all working axes | standard-type |

| No.1 milling cutter dia. 16 16 | standard-type |

| No. 1 milling cutter dia. 14 14 | standard-type |

| No. 1 bit dia. 7 | standard-type |

| Dimensions | 2600 x 3400 x 1750 mm |

| Weight | 1200 kg |

| Container load dimensions | 2300 x 3200 x 1765 mm |

| Kit for frame machining | Door loading/unloading roller conveyors |

| Feeler pin to identify millimetric differences in the width and thickness of the workpiece |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472