ELITE 400

Wood Tenoning Machine

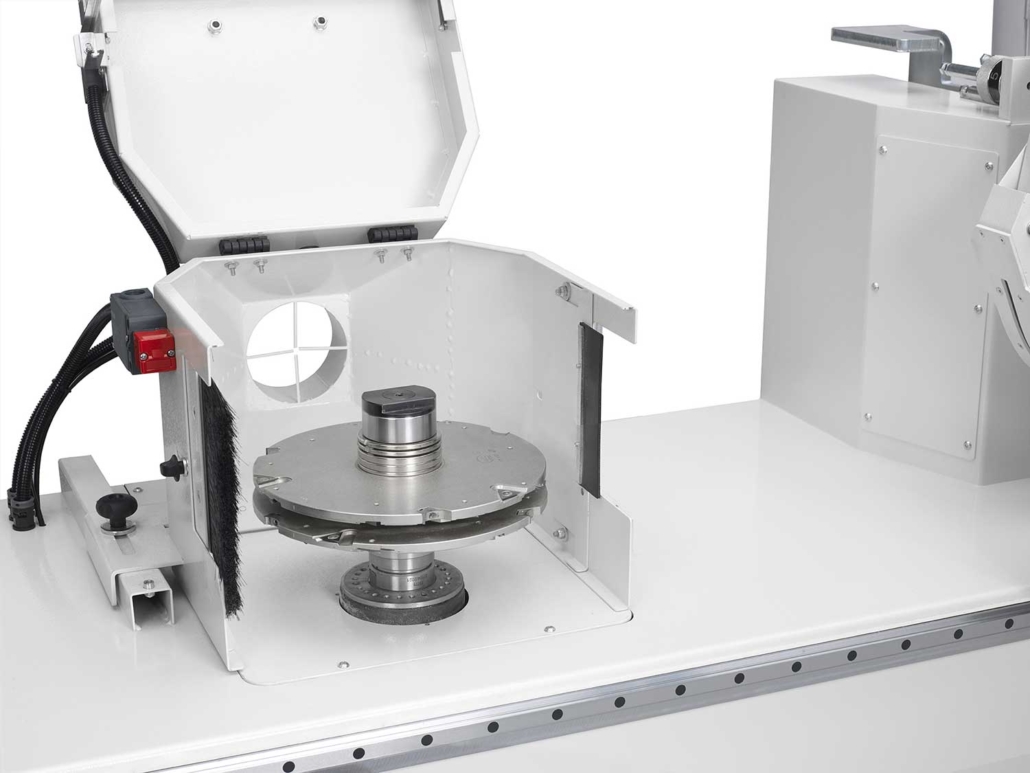

Elite 400 is a tenoning machine complete with a blade unit and a vertical tenoning spindle.

Entirely overhauled design to provide customers with maximum protection, applying all the safety features required by law, and to market a product with modern mechanics.

Advantages in wood tenoning

- Two different versions

- Circular saw unit

- Positioning via revolver

- Modern mechanics

- In compliance with EU regulations

- In-house production

Version ELITE 400 E

In the Elite 400 E version, the machine comes complete with a HITECO electric spindle for rapid shaft change using the HSK 63B system, and with 4 spindles supplied.

Vertical stroke of 90 mm under the work surface with readable measurement on the mechanical readout.

Motor power 7.5 kW.

Version ELITE 400

In the Elite 400 version, the machine comes complete with a spindle with a tool change system by means of a ring nut; its 90 mm reach under the work surface allows the housing of a variety of tools for quick work change.

Vertical positioning readable on the mechanical display.

Circular Saw Unit

Circular saw with a rotation speed of 2800 rpm.

The maximum permissible cutting height is 120 mm, with transverse movement, again of 120 mm.

A 5-position revolver is provided for quick setting.

Surface Unit

Positioning of the work surface in relation to the tool diameter by means of a 5-position revolver, the unit is moved on linear guides and recirculating ball bearings.

Work rail tiltable to +/- 45 degrees.

Workpiece Clamping

Wood clamping takes place by means of 2 vertical cylinders and 1 horizontal cylinder, so that workpieces up to 400 mm wide can be machined or two identical workpieces can be tenoned simultaneously for considerable time savings.

| Data | Value |

|---|---|

| Standard spindle | Standard |

| HITECO Electrospindle | – |

| Shaft diameter | 40 or 50 mm |

| Max tool diameter | 360 mm |

| Stroke under the working table | 90 mm |

| Speed rotation (Toolholder Shaft) | 3600 rpm |

| Motor power (Toolholder Shaft) | 7,5 kW |

| Fast tool change | Ghiera |

| Shaft included | – |

| Max blade diameter | 400 mm Standard (450 mm Optional) |

| Max cut height | 120 mm |

| Speed rotation (Saw Blade Unit) | 2800 rpm |

| Motor power (Saw Blade Unit) | 3 kW |

| Guide tilting | +/- 45° |

| Manual rotating chipbreaker for 90° machining | Standard |

| Pneumatic workpiece clamping by vertical pressers | no. 2 |

| Pneumatic workpiece clamping by horizontal presser | no. 1 |

| Data | Value |

|---|---|

| Standard spindle | – |

| HITECO Electrospindle | Standard |

| Shaft diameter | 40 or 50 mm |

| Max tool diameter | 360 mm |

| Stroke under the working table | 90 mm |

| Speed rotation (Toolholder Shaft) | 3600 rpm |

| Motor power (Toolholder Shaft) | 7,5 kW |

| Fast tool change | HSK 63B |

| Shaft included | nr. 4 |

| Max blade diameter | 400 mm Standard (450 mm Optional) |

| Max cut height | 120 mm |

| Speed rotation (Saw Blade Unit) | 2800 rpm |

| Motor power (Saw Blade Unit) | 3 kW |

| Guide tilting | +/- 45° |

| Manual rotating chipbreaker for 90° machining | Standard |

| Pneumatic workpiece clamping by vertical pressers | no. 2 |

| Pneumatic workpiece clamping by horizontal presser | no. 1 |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472