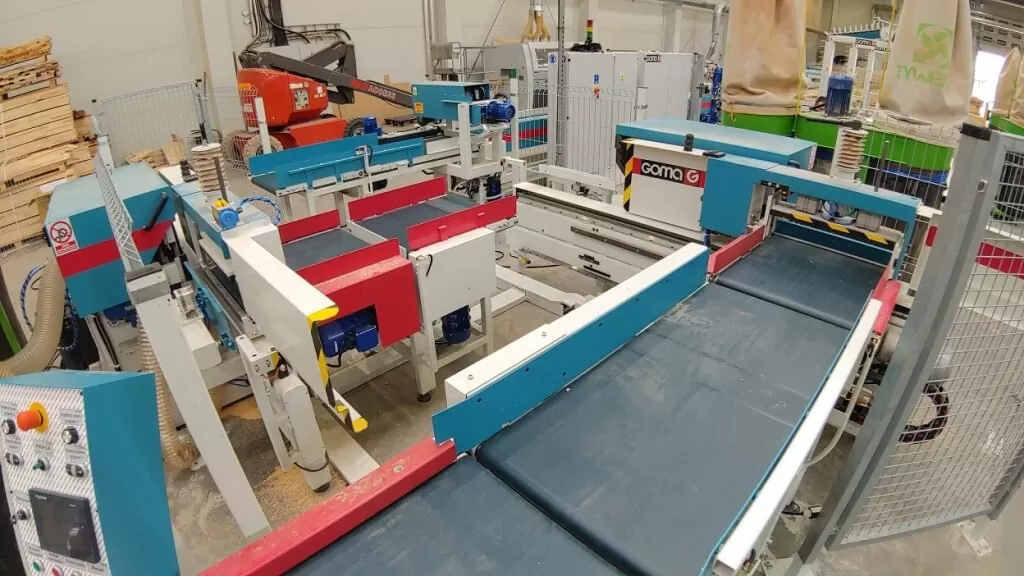

GOMA – FC-10 Double Tenoner Finger Jointing Line

Industrial capacity line

Wood finger jointing line FC-10 TWIN by GOMA is a more extensive model of the first, FC-10, version. The line has the same processing parameters as its predecessor, however, thanks to the use of 2 tenoning machines, has much-increased efficiency.

Characteristics:

- set for making micro-grip joints for large-scale and mass production

- able to produce 2 patterns of finger joints: zig-zag wood joint and line-style wood joint (vertical and horizontal)

- 1-person service

- high capacity

- production line with the highest capacity

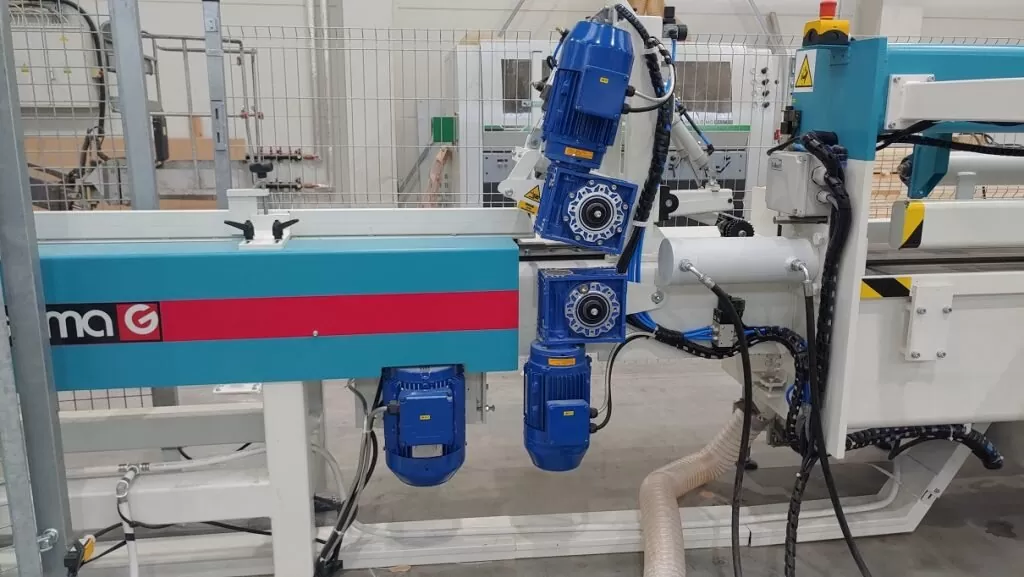

- high-power working power generators

- high working feeds

- accelerated handling movements translate into high performance. Depending on the assumed capacity, additional buffering conveyors are built into the string, which speed up the production process

Wood finger jointing line FC-10 Double – STANDARD EQUIPMENT:

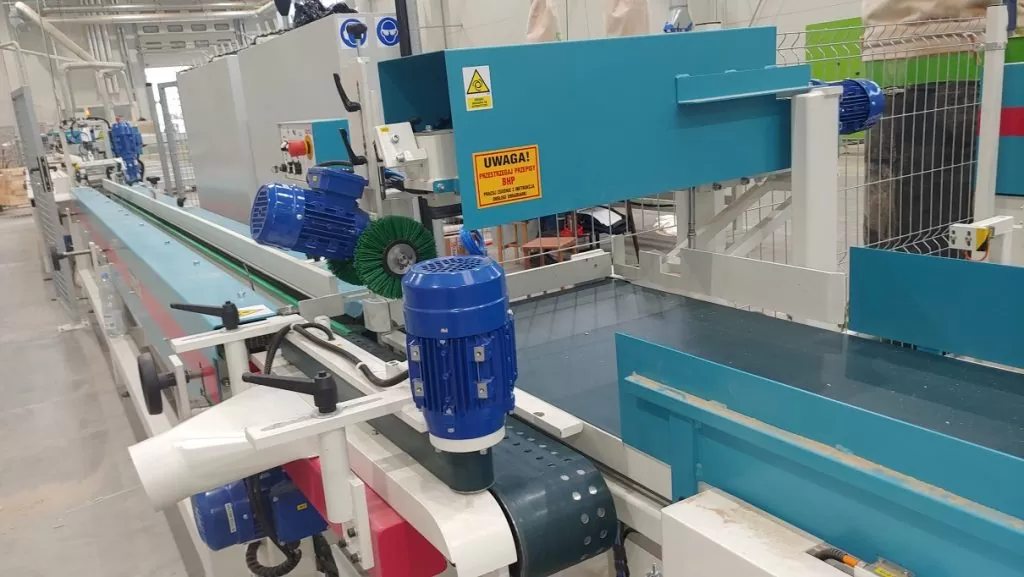

- chain feeder in front of the press

- upper cutting unit – 2 pcs.

- bottom cutting unit – 2 pcs.

- turning machine

- device for cutting to lengths

TENONER FC-10 KZ6

PRESSING UNIT FC-10 PZ6/2

| Data | Value |

|---|---|

| Milling Spindle | Ø 50×210 mm |

| Spindle Rotations | 6000 r/min |

| Motor | 18,5 kW |

| Tool Dimensions | Ø 250×160 mm |

| Sawing Spindle | Head Trim |

| Special Chipper | Ø 300×8 mm |

| Motor | 6 kW/ 3000 r/min |

| Table | Smooth Feed |

| Width x Height | 600 x 30÷160 mm |

| Glue Nozzle | Same Shape as Cutter |

| Data | Value |

|---|---|

| Element width min./max. | 30 mm/155 mm |

| Element thickness min./max. | 20 mm/55 mm |

| Length of Finished Board | 6050 mm |

| Pressing Force | 3 – 7.5 – 10T |

| Hydraulic Power Pack | 3 kW/100 (140) bar |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472