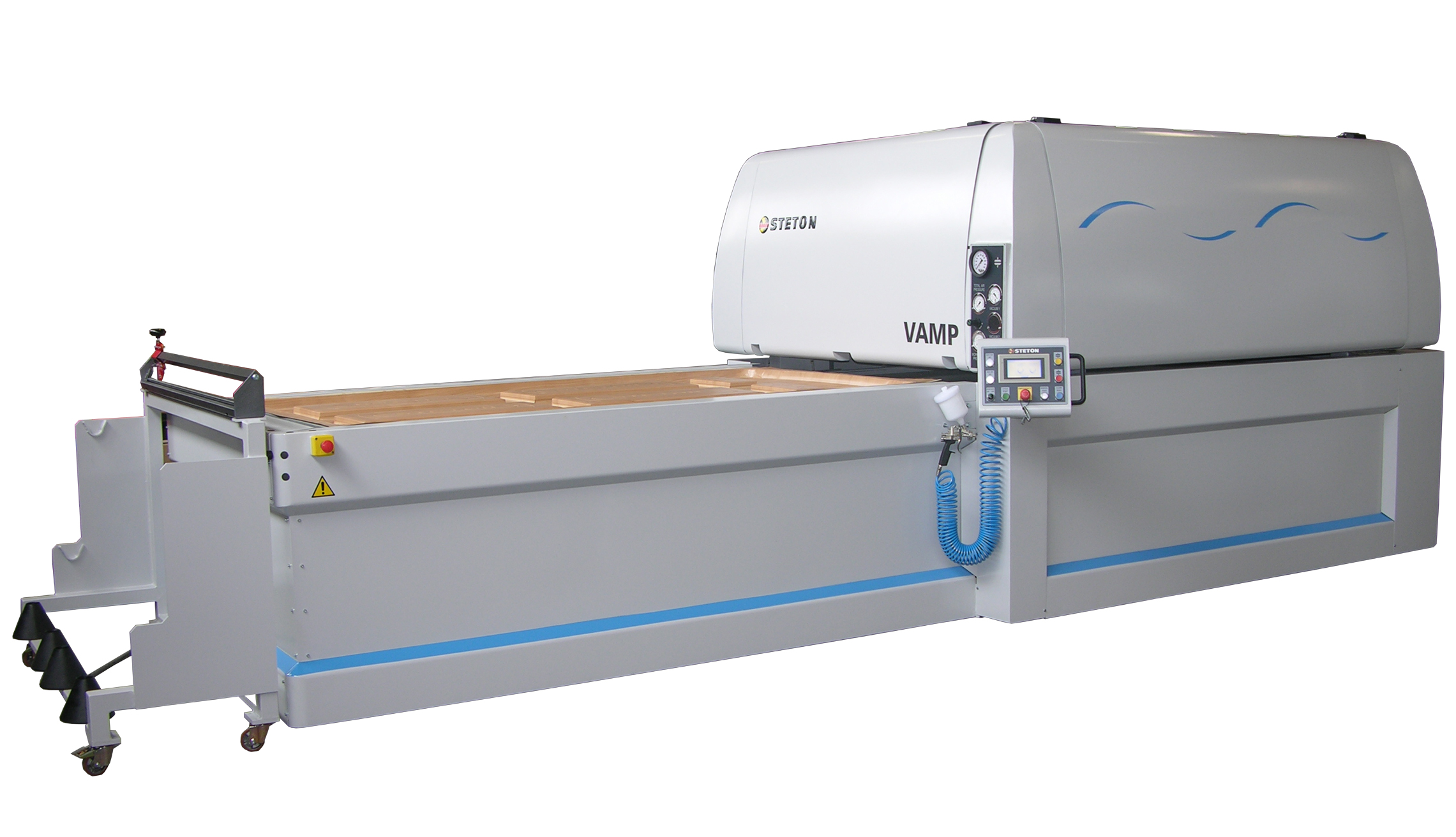

VAMP

VAMP is different from other models as it can be equipped on request with two loading/unloading trays that are alternatively introduced and extracted from the two sides of the press by a motorized system.

This system allows to prepare on one of the two trays the new material during the pressing cycle of the other tray inside the press. In the same way the trimming of the foil edges is done during the pressing of the other material inside the press. In this way dead times are minimized.

The main purpose of the air press is the covering of raised panels, normally made by MDF, with PVC foils, to produce for instance kitchen doors or similar items.

The cycle process is the following:

- Disposition of the pre-glued panels – placed onto templates – on the bottom tray.

- Covering of the bottom tray, with perimetric gasket, with the PVC foil.

- Cutting of PVC at right lenght (through the manual shear, optional).

- Automatic introduction of the tray into press (with double tray, optional, the loading/unloading movement is on the two sides of the press).

- Closing of press.

- making of vacuum from the top. In this way the PVC (or other thermoplastic foil) is attracted towards the top press platen, that through the heating makes the foil soft.

- Supply of top pressure through heated air. Creation of bottom vacuum by means of a high-vacuum pump through a drilled grid placed in the bottom of the tray. The combination of top pressure and vacuum allows the perfect forming of the thermoplastic foil onto the raised panel.

- Short stop inside the press.

- Opening of the press, extraction of the tray and trimming of the PVC all around the panel edge.

Our models can also be equipped on request with an easily extractable top air membrane (optional), allowing to apply veneer (thickness 0,4 mm.) on raised or flat panels.

Optional:

- Second tray for loading/unloading at the other side of the press.

- Frame with membrane: 25/14 – 30/14

- Spare membrane: 25/14 – 30/14

| Data | Value |

|---|---|

| Specific working pressure | 4,5 Kg/cm2 |

| Cylinders diamter | Ø 85 mm |

| Cylinders stroke | 120 mm |

| Tray outside dimensions | 2550×1450 / 3050×1450 mm |

| Tray inside dimensions | 2390×1290 / 2890×1290 mm |

| Useful working dimensions | 2350×1250 / 2850×1250 mm |

| Nr. of pressing cylinders | 8 – 10 |

| Total pressure | 160 / 200 tons |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472