BUMERANG S1

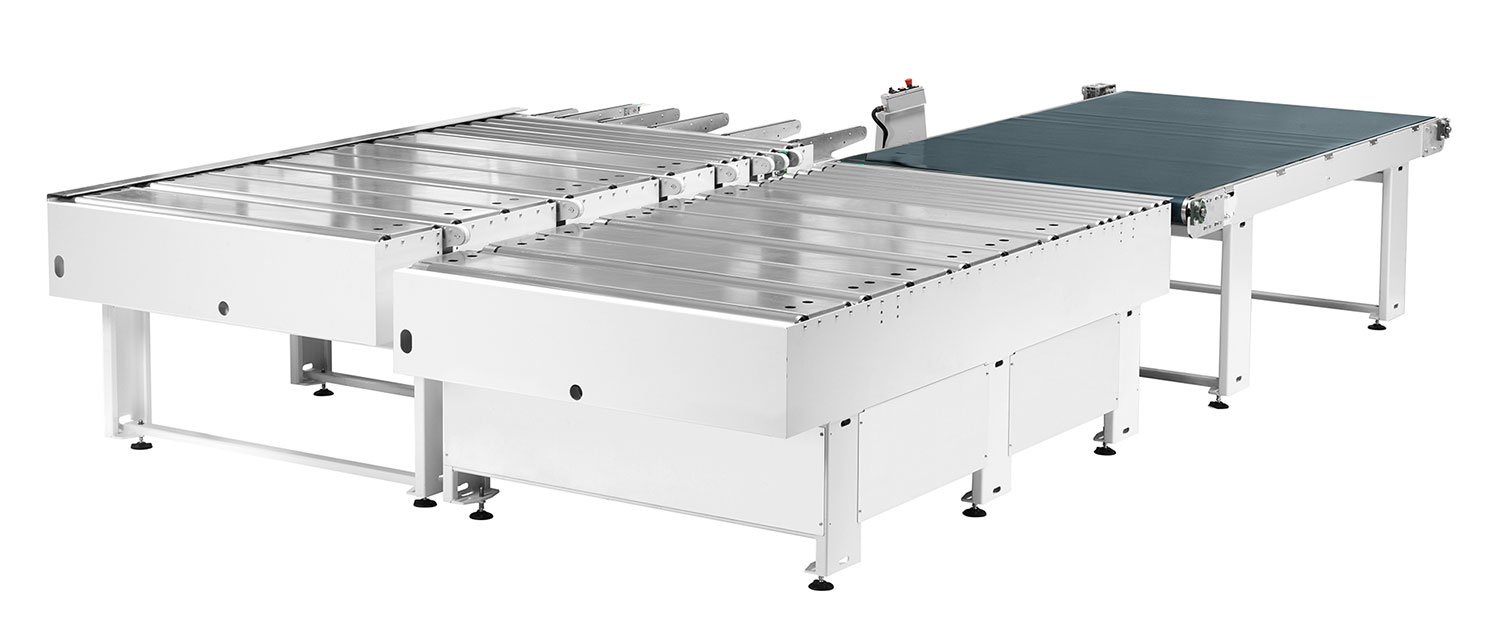

BUMERANG S1 workpiece return roller conveyor

The BOOMERANG S1 workpiece return roller conveyor is the optimal complement to your edgebanding machine: an excellent automatic wood panel handling system that was created as a perfect addition to single-layer edgebanding machines.

Thanks to this Futura Woodmac solution, the workpiece return system to the operator’s station minimizes the use of personnel while increasing the profitability of the edgebanding machine, regardless of the type of production (on order, series or batch).

With its sturdy and stable design, the roller conveyor connected to the edgebanding machine brings significant benefits to both large industrial enterprises and, where automation is becoming increasingly popular, small businesses.

In addition, the automatic handling system, operated through the Boomerang (with rollers, belts, and conveyor belt), makes it possible to process parts and panels (whether large or small) of all sizes.

Advantages in panel handling

- Easy handling

- Robust structure

- Greater panel integrity

- Cutomisations

- In compliance with EU regulations

- In-house production

Arms for workpiece input into the roller conveyor

Machine complete with 5 arms with adjustable positioning to connect the edgebanding machine with the roller conveyor.

Each arm has a motorized belt to transport the workpiece into the roller conveyor.

Sliding surfaces

Motorized sliding surfaces complete with rollers and belts to transport the panel to the belt.

Conveyor belt

At the end of the stroke, the workpiece reaches the operator via the conveyor belt (with a width of 1500 mm and a length of 2700 mm).

Remote control panel

For maximum efficiency and safety, the workpiece handling system can be operated by the operator (in a position in front of the edgebanding machine) via a remote push-button panel.

Thanks to this device, the machine operator can effectively start or stop the work cycle, operate the emergency system in the event of danger, and manage the unloading of linear material at the edgebanding machine.

Therefore, for each of these operations, it will not be necessary to return to the operator.

| Data | Value |

|---|---|

| Min – max workpiece length | 150 – 2500 mm |

| Min – max workpiece width | 50 – 1500 mm |

| Max weight | 100 kg |

| Feeding speed | 25 mt/min |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472