PROGRAM

Wood 4 Sided Planer Moulder Machine PROGRAM

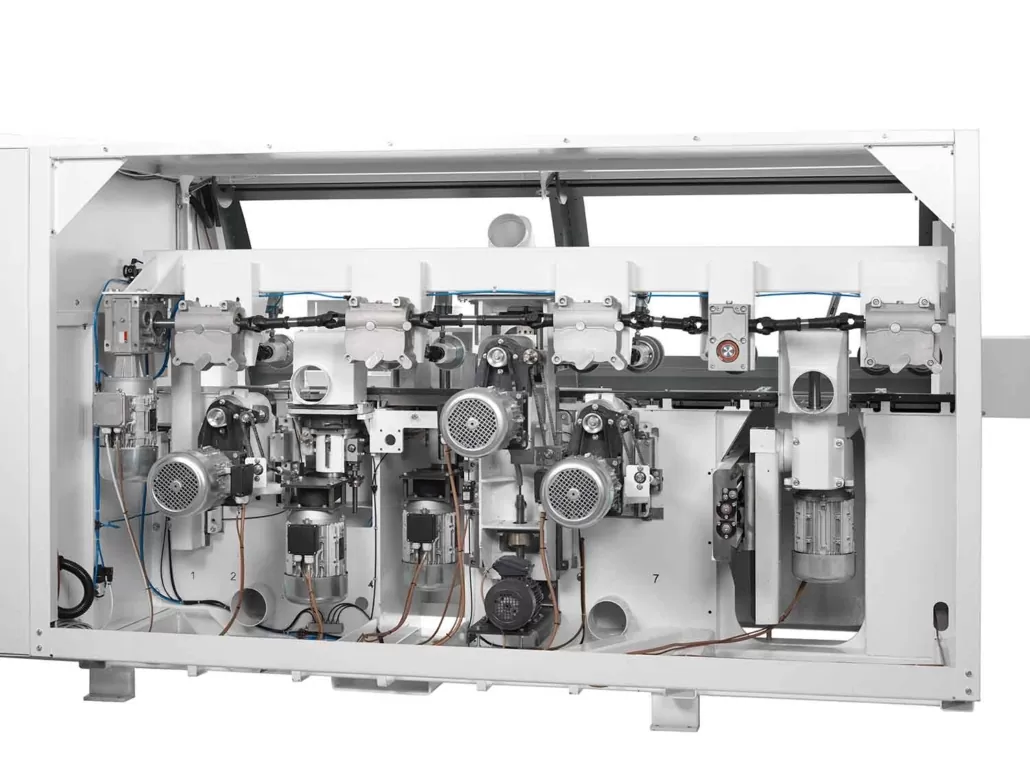

PROGRAM is a high-capacity 4 sided planer moulder, designed to meet specific requirements in industrial woodworking: heavy workloads without interruptions, large pieces (as wooden beams, for example).

This model meets all needs, adopting mechanical and technological innovations that make it extremely performing in the production results, with a new version that now reaches a working width of 300 mm (with horizontal spindles of 50 mm diameter) and features the unit handling on linear guides and ball runner blocks.

The reliability of the machine (for stability and wear resistance without maintenance) is guaranteed by the worktables in Hardox HB400 (top-of-the-range material) and the drive gearboxes.

Also Wooden Beam Processing

The PROGRAM model in all its 13 versions is ideal for not only straightening/planing and moulding operations, but also for processing beams.

It is possible to work at a maximum width of 300 mm.

The settings are varied and can have up to 8 spindles, and thanks to the 90 mm range of the vertical spindles the machine can be equipped with different tools so as to switch between a production process and another in a short time.

Advantages in Woodworking

- Woodworking max 300×180

- Sturdy structure

- Heavy workloads

- Instant tool replacement

- Maximum safety (according to the UE)

- Testing and trials prior to delivery

- In-house manufacturing of the machine body

- Quality at very competetive prices

- Drive gearboxes for workpiece conveying

- 90 mm vertical shaft axis stroke

Working capacity

The maximum working sections are 300 mm in width (minimum 25 mm, optional 15 mm) and 180 mm in height (minimum 10 mm, optional 200 mm).

Uninterrupted heavy workloads

The top of range Hardox worktable, with its solidity and perfect grip, guarantees excellent wear resistance with very low risks of breakage.

It is the ideal choice for high-production in uninterrupted lines.

Simple and quick operation

All the everyday activities (from machine setting to checking the end piece) are made easier by the new mobile console, designed for maximum efficiency by our technical department.

Drive system reliability

The drive system is extremely reliable over time and is maintenance-free thanks to its sturdiness and resistance.

Its cardan-shaft oil-bath drive gearboxes ensure a perfect finishing with no vibrations on wood.

Continuous machining with lower consumption

The presence of the gearmotor ensures a stepless production, even under heavy working conditions.

Furthermore, by applying high reduction ratios, a higher motor performance reduces power consumptions resulting in reduced machining costs.

New technologies for greater efficiency

We believe in the application of new technologies in providing greater efficiency.

Innovation is key to achieving better performance in terms of quality and production times.

On the Program machine, you can find state-of-the-art handling technologies – i.e. linear guides and ball runner blocks – which give instant and greater advantages with respect to that of competitors.

Linear guides and ball runner blocks

The Program machine has been designed with genuine state-of-the-art handling technologies, like the presser in the 3rd unit with movement on the linear guides and ball runner blocks with the addition of rubber pressure elements horizontally positioned to keep the wood in position.

The same handling system has been used for upper shaft and the connected drive unit upstroke and downstroke.

Linear guides, with their ball runner blocks – if any – move the second upper shaft.

Compact drive system

Thanks to their ribbed structure, the Poly-V belts allow for a very compact drive even in heavy workload conditions.

The pulleys are perfectly coupled to belt grooves, also ensuring absence of vibrations and noiseless performance.

Air-cushion worktable

Workpiece feeding, even in case of difficult wood machining, is however guaranteed by an air-cushion worktable, fitted with 3 rows of holes that can be activated individually, as required.

In combination with air cushioning, workpiece conveying can be improved by an optional air and oil atomisation system.

Machine Performance

The Program machine can be fitted with 110 mm to 200 mm diameter tools.

The vertical shafts’ axis stroke is of 90 mm to machine a higher number of profiles and and allow a rapid work change.

The maximum work sections are 300 mm in width and 180 mm in height (200 mm as an option).

The minimum work sections are 25 mm in width (15 mm optional) and 10 mm in height.

Quality Control and Testing

The production of the Program machine includes, as a standard, the mechanical quality control as well as its testing – even with tools supplied by the customer.

Sophisticated size control tools verify every tolerance and critical dimension, to eliminate any problems or failure risks during assembly.

Automatic management of main positioning

Machining becomes intuitive and instant via the colour modern touch screen of the PLC – graphics designed in detail by our staff. This automatically controls the main positions.

This control includes:

- manual, semi-automatic and automatic positioning of axes;

- saving a large number of programs;

- shaft and drive motors actuated via a single button;

- automatic correction of tool data.

(optional piece)

Colour Touch Screen

The Program machine comes with a state-of-the-art technology.

As an option, you can choose among a 7, 10 or 15 inches Touch Screen.

Easy and fast to program, you will save time and reduce any risk of errors during the setup steps.

You will have the possibility to control a higher number of axes, thus customising your operator interface.

(optional piece)

Mobile working width

The mobile working width option is extremely useful when working with different unfinished material widths.

The device records sizes automatically transmitting it them to the plc that will then position the shaft on the correct measurement value.

The system is driven by a ball-screw system and can be switched off with a simple click.

(optional piece)

3rd Shaft drive and electronic displays

Via a couple of pushbuttons – as a cheaper alternative to the PLC – you can easily set the working width and height. One is for the shaft quick handling, and the other is for a tenth of a millimetre positioning.

(optional piece)

| Data | Value |

|---|---|

| Max. Working width (with tool dia 125 mm) | 300 mm |

| Min. Working width (with tool dia 125 mm) | 25 mm |

| Max. Working height (with tool dia 125 mm) | 180 mm |

| Min. Working height (with tool dia 125 mm) | 10 mm |

| Feed speed with inverter | 4/30 m/min |

| Shaft rotation speed | 6000 rpm |

| Horizontal shafts diameter | ø 50 mm |

| Vertical shafts diameter | ø 40 mm |

| Tool diameter 1st horizontal spindle | ø 125 mm |

| Min tool diameter 4th spindle | ø 110 – 125 – 140 mm |

| Max tool diameter 4th spindle | ø 200 mm |

| Minimum and maximum diameters for milling cutters of all the working shafts (except 1st and 4th shafts) | ø 110 / 200 mm |

| Milling cutter diameter and thickness | ø 145 – 12 mm |

| Length of infeed worktable | 2500 mm |

| Vertical shaft axial adjustment with respect to worktable level | 90 mm |

| Planer shaft motor power | 10 hp (7,5 kw) |

| Right spindle moulder motor power supply | 7,5 hp (5,5 kw) |

| Left spindle moulder motor power supply | 7,5 hp (5,5 kw) |

| Upper horizontal motor power supply | 10 hp (7,5 kw) |

| Lower 2nd motor power supply (if fitted) | 10 hp (7,5 kw) |

| Upper 2nd motor power supply (if fitted) | 10 hp (7,5 kw) |

| 2nd right spindle moulder motor power supply (if fitted) | 7,5 hp (5,5 kw) |

| 2nd left spindle moulder motor power supply (if fitted) | 7,5 hp (5,5 kw) |

| Universal motor power supply (if fitted) | 7,5 hp (5,5 kw) |

| Feed motor power supply | 4 hp (3 kw) |

| Lifting motor power supply | 0,5 hp (0,37 kw) |

| Hardox hb400 worktable | standard |

| Feeding system via cardan-shaft drive gearboxes | standard |

| Pneumatic pressure on the driving rollers | standard |

| Poly-v belt drive system on every tool holder shafts guarantees maximum motor power supply performance | standard |

| Each tool holder shaft is equipped with an individual motor | standard |

| Air cushion worktable to ease wood handling | standard |

| Manual lubrication of the worktable | standard |

| Pneumatic pre-planer roller with exclusion from control panel | standard |

| Minimum working width 15 mm | 3rd unit motorised adjustment |

| Automatic lubrication of the worktable | Bright led displays |

| Automatic/manual lubrication of the guides | 2 axes / 4 axes / 6 axes / 8 axes programmer |

| Automatic/manual lubrication of the vertical spindle moulders | Motor power supply increase |

| Drive shaft extension | Set of planing tools |

| Short-piece device | High-precision 8000 rpm spindles |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472