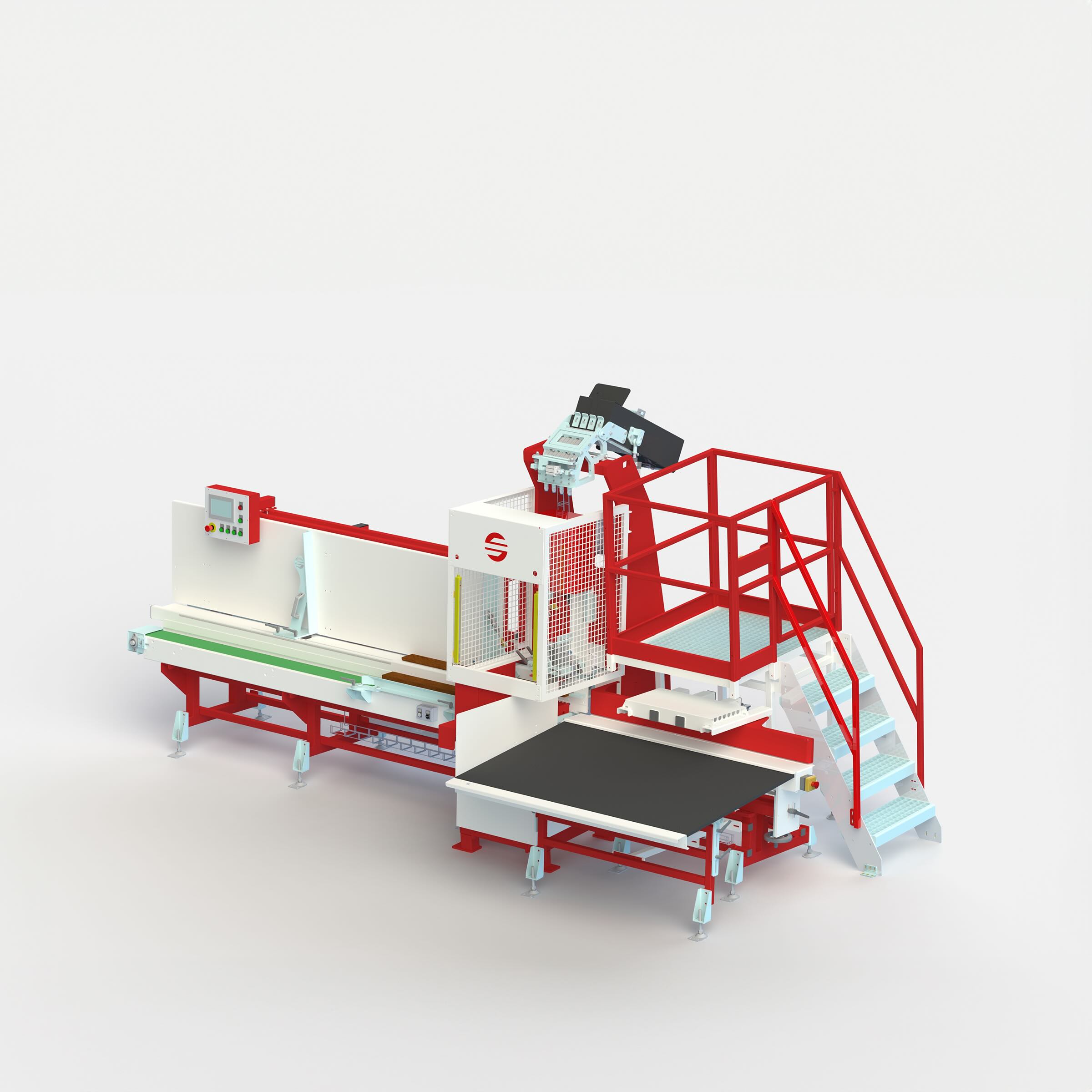

Störi Mantel – Leg Machine

SMLM – 4K ED 1500/3000

The Störi Mantel Leg Machine is an automatic device for producing the bottom parts of wooden pallets, also known as pallet bases or legs, which operates on the proven principle of electromechanical nailing.

The main key features that will increase your production capacity, save on operational and personnel costs, and speed up the entire pallet nailing process include, for example, the production cycle speed, the possibility of integration with other equipment such as a cross-cut saw or pallet nailing machine, convenient operation of the entire machine by a single operator, and easy maintenance and servicing. The Leg Machine can be designed with a maximum leg length of 1 500 mm or 3 000 mm.

Easily, quickly, and effortlessly

With the Störi Mantel Leg Machine, you can produce legs of various constructions while ensuring maximum work safety. The machine operates with solid or glued blocks and always uses boards of a consistent dimension. In the control panel, you can set up to 40 nailing programs, specifying the length of the leg, the number and placement of blocks, and the nailing pattern, which is always within a tolerance of +/- 1 mm.

Reduce costs not only for energy due to the electromechanical nailing system

The nailing system utilizes an electromechanical drive and has one of the lowest power consumptions in its class. Additionally, you won’t have to worry about maintaining and operating a hydraulic nailing system (refilling, replacing, and disposing of oil, excessive noise, etc.), as is the case with machines available on the market.

Increase capacity and maximize production

The pallet base nailing machine will provide you with semi-finished products ready in the appropriate quality and quantity for completing the entire pallet. You will insert already finished legs into the nailing machine, eliminating the need to prepare them beforehand. This will accelerate the entire process by up to 12 seconds/pallet. The Störi Mantel Leg Machine can also be used in operations where pallets are nailed manually using pneumatic nailing guns.

Smartly save on production material in the form of loose nails

Because all Störi Mantel nailing machines work with loose nails of all available and suitable types, including EPAL nails, you don’t need to unnecessarily pay for strip nails, which are significantly more expensive.

| Data | Value |

|---|---|

| Capacity | 6-9 pcs/min. |

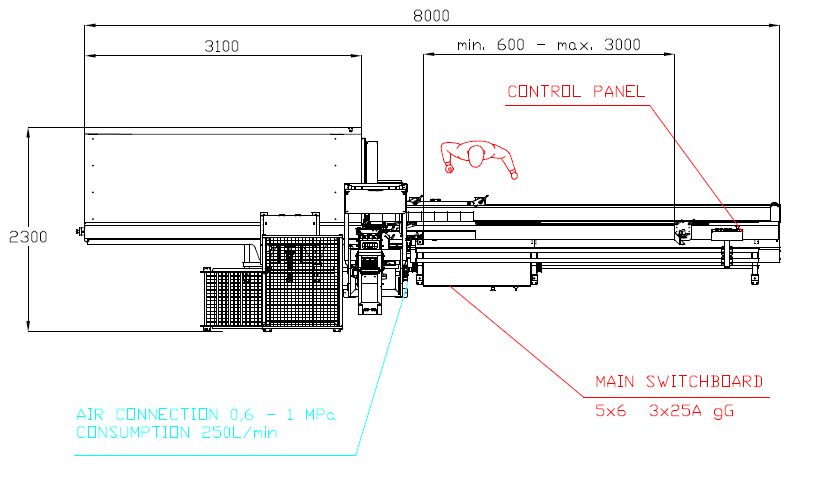

| Length | for 1 500: 5 000 mm, for 3 000: 8 000 mm |

| Width | 2 300 mm |

| Height | 3 000 mm |

| Weight | for 1 500: cca 2 100 kg, for 3 000: cca 2 500 kg |

| Feeding device speed | up to 2 m/s |

| Data | Value |

|---|---|

| Electrical power consumption | 3,35 kW |

| Fuse | 3 x 25A |

| Voltage | ~ 3×400 V/50 Hz |

| IP protection | IP 54 / IP 20 |

| Data | Value |

|---|---|

| Compressed air supply pressure | min. 0,6 MPa – max. 1 MPa |

| Capacitive air consumption | 250 l/min. |

| Data | Value |

|---|---|

| Maximum size (L x W x H) | for 1 500: 1 500 x 150 x 25 mm, for 3 000: 3 000 x 150 x 25 mm |

| Minimum size (L x W x H) | 600 x 60 x 12 mm |

| Capacity of the plank tray | 32 pcs (20 mm thick plate) |

| Data | Value |

|---|---|

| Maximum size (L x W x H) | 150 x 150 x 100 mm |

| Minimum size (L x W x H) | 60 x 60 x 60 mm |

| Capacity of the cube tray max. | for 1 500: 15 pcs (cube 100 mm long), for 3 000: 30 pcs (cube 100 mm long) |

| Data | Value |

|---|---|

| Nails | All bulk nails intended for machine hammering with a length of 50 – 70 mm, including EPAL nails. |

| Nail Box | 1x box with 4 outlets |

| Box capacity | 4 kg |

| Hammers | 4 pcs (punch diameter 10 mm) |

| Minimum nail pitch | 25 mm |

| Tolerance of maximum accuracy of nail strike position | +/- 1 mm |

| Tolerance of driving nails | +/- 0.5 mm |

| Nailing cycle | The time of the nailing cycle depends on the length of the nailed leg and the number of nailing positions (cubes). |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472