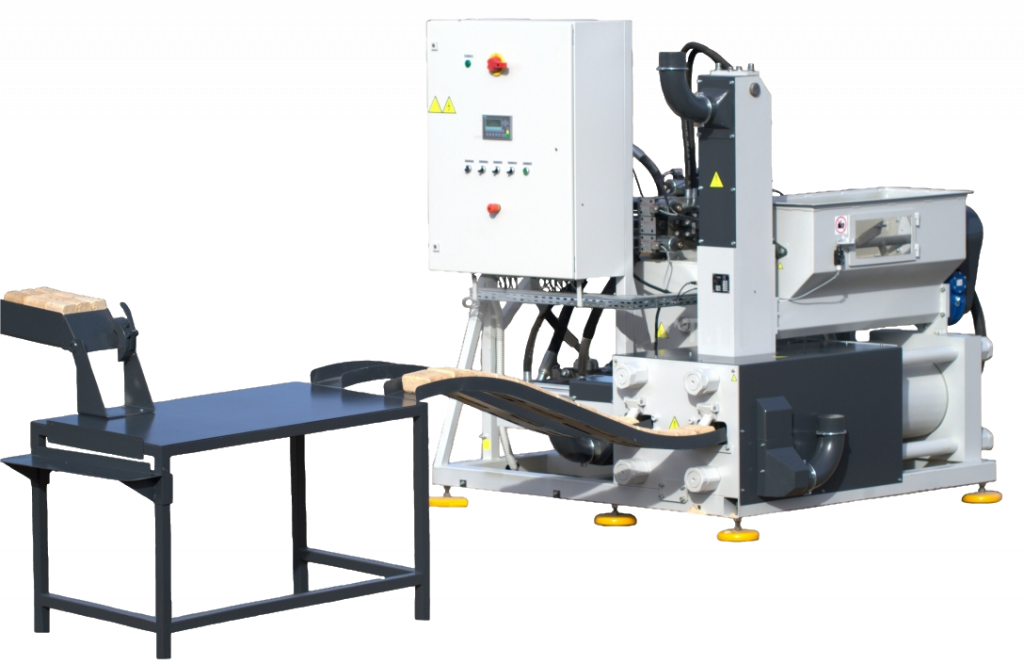

BP500A

Efficiency up to 600 kg/h

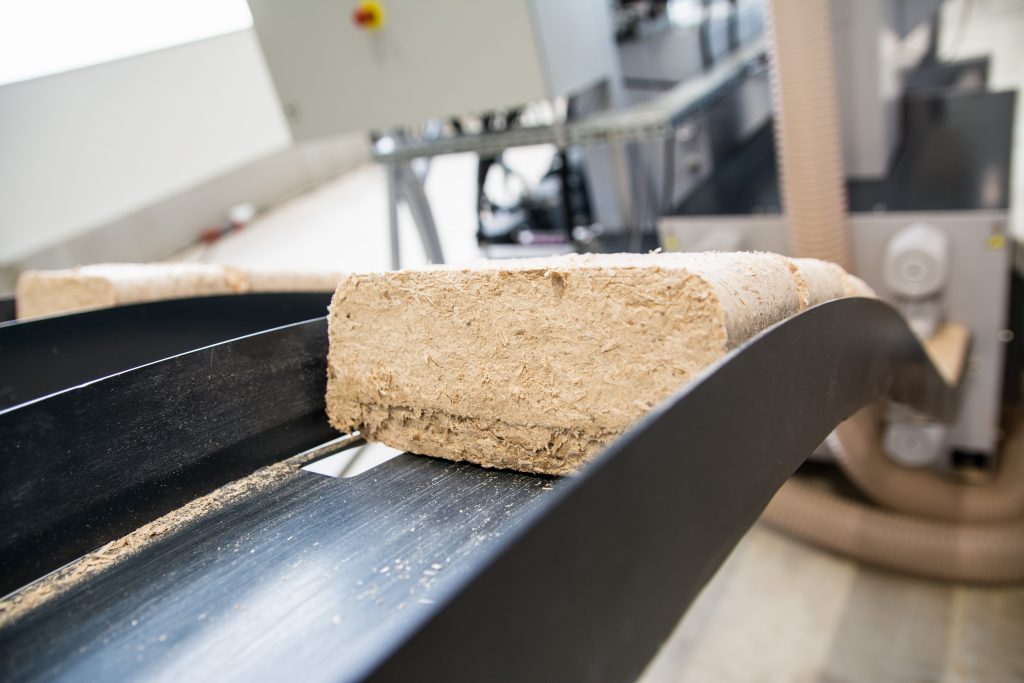

Let’s not waste the profits anymore. Sawdust, biomass, and even aluminum swarf leftovers from the manufacturing process are usually discarded – this means a loss of potential profits. Turning your manufacturing scraps into briquettes is one of the best ways to creae additional value. This is a job for an automated hydraulic briquette press BP500A.

It produces up to 600 briquettes per hour and can tackle non-stop operation 24/7. It could also be used for pressing non-ferrous metal, paper, or any secondary product of the farming industry. Hydraulic briquette press BP500A meets all the requirements of the EU and also is certified as a ‘Green Energy’ product.

Features:

- Administered by a SIEMENS HMI controller

- Manual and automatic modes of operation

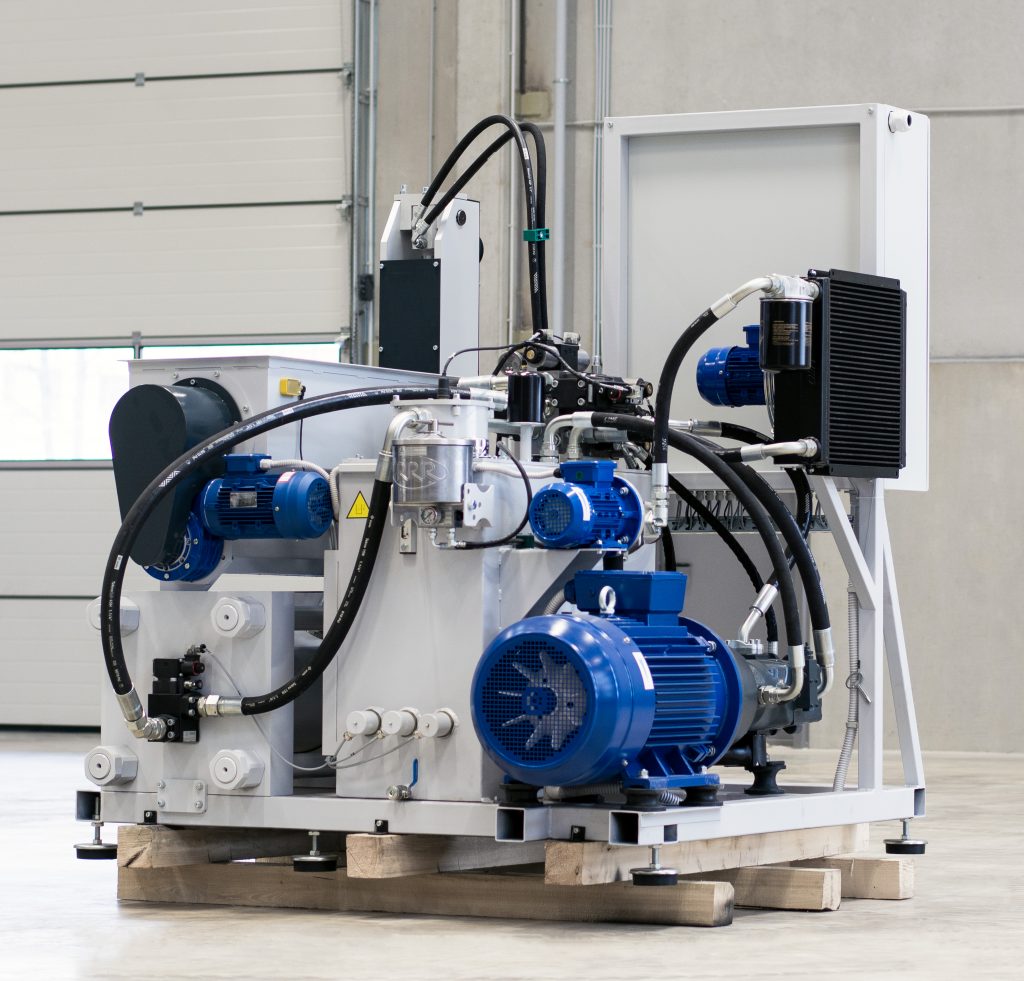

- Abrasion-resistant, hardened internals

- Capable of non-stop 24/7 operation

- Adjustable size and weight of briquettes

- Proven reliability

- Modular design adapts to client’s facilities

Included with the machine:

- Key for the machine

- Hydraulic oil

- Operating manual

- CE Certificate

- Briquette guides

- Manual packing table

- Manual packing rack

- Manual bag sealer for PP, PE and PVC bags

Additional options:

- Oil heater (for operation in negative temperatures -0C ~ -20C)

- Twin-cooler for operating in tropical environments

- Installation and training

- Extended hopper

Additional optional products:

- UB-180 sawdust bunker

- Custom conveying solutions

- Automated packing and palletizing system

| Data | Value |

|---|---|

| Capacity | <600briq> |

| Pressing max | 1700 kg/cm² |

| Sawdust humidity max | 15% |

| Length | 1800 mm |

| Width | 1800 mm |

| Height | 1900 mm |

| Height during transportation | 2200 mm |

| Weight | 3000 kg |

| Electricity | 380 V 50 Hz |

| Power | 33 kW |

| Current | 70 – 100 A |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472