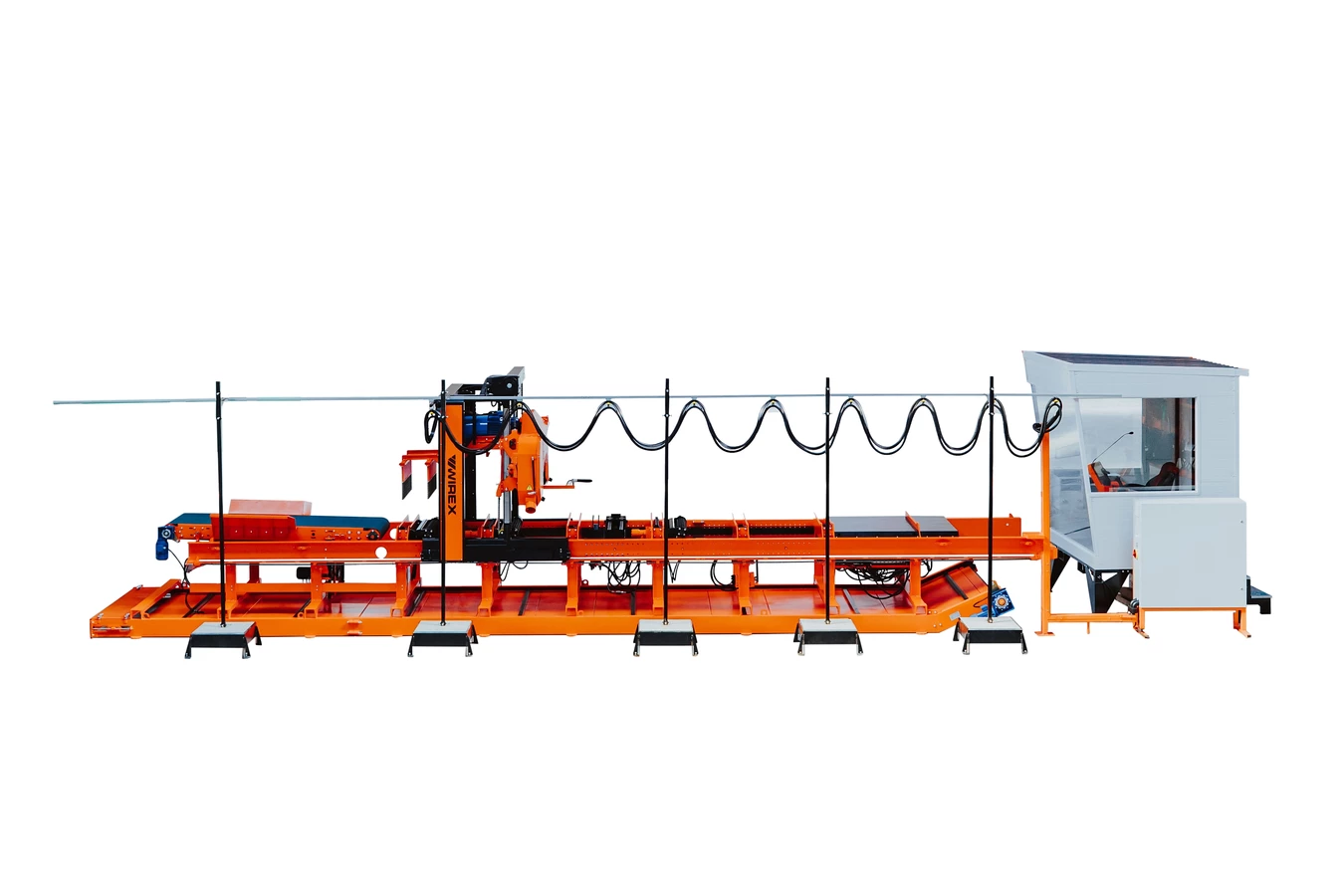

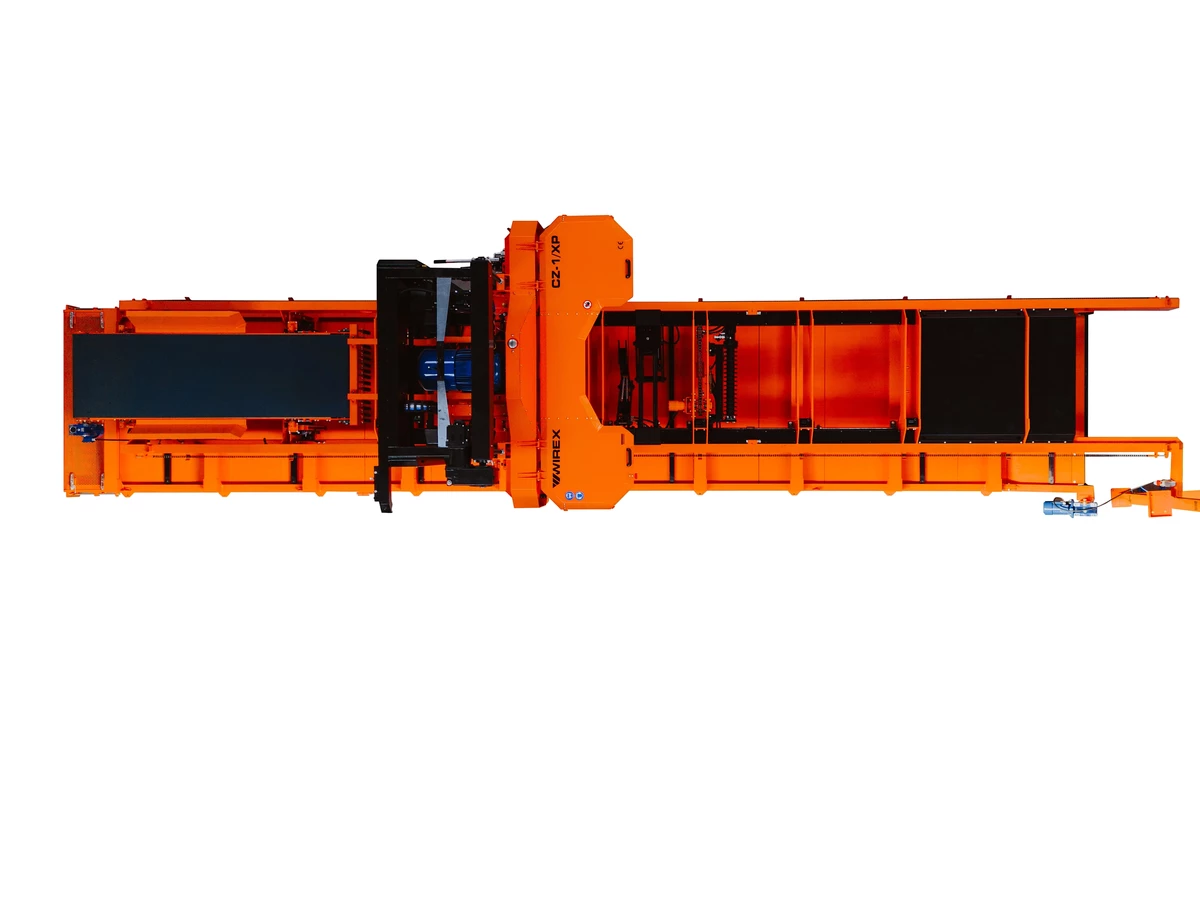

CZ-1/XP Sawmill

The CZ-1/XP is a next-generation sawmill featuring cutting-edge technological solutions developed through our research and development efforts. Designed to enhance efficiency and precision, this sawmill integrates advanced automation and innovative features that streamline the production process. With improved performance and user-friendly controls, the CZ-1/XP is ideal for meeting the demands of modern woodworking operations, ensuring you achieve optimal results in every project. Experience the future of wood processing with the CZ-1/XP.

Optional equipment

- moving floor for extraction of saw dust and wastes from the sawmill

THE MOVING FLOOR IS THE SUBJECT OF A CLAIM AT THE PATENT OFFICE - debarker

- claw log turner

- clamp

- roller conveyor with sorting function ( lefward / rightward)

- roller conveyor without drive

- roller conveyor with drive (collection of drag-back elements)

- loading ramp RZ/CZ-1 wide

- loading ramp RZ/CZ-1 heavy duty (chains built-in the loading arms)

- additional cameras (max. 6)

- wider blade up to 75 mm

| Data | Value |

|---|---|

| Dimensions |

|

| Weight | 4 500 kg |

| Log diameter | 900 mm (band saw guiding rollers inter-distance 900 mm) |

| Length of cut (standard) | 8000 mm |

| Main motor power | 20 kW (high torque low speed) |

| Power supply | 400 V (3-phases) |

| Innovative cutting head |

|

| Band wheels diameter | 700 mm |

| Band saw specification |

|

| Implemented technologies |

|

| Blade tension roller slide | adjustable – joystick controlled |

| Transport belt dimensions | sawmill frame with built in belt conveyor for collection and extraction elements drag-back with cutting head – length 2000 mm |

| Thickness of cut setting |

|

| Hydraulic |

|

| Capacity per hour | up to 5 m3 |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472