FDR

Trimming saw for boards

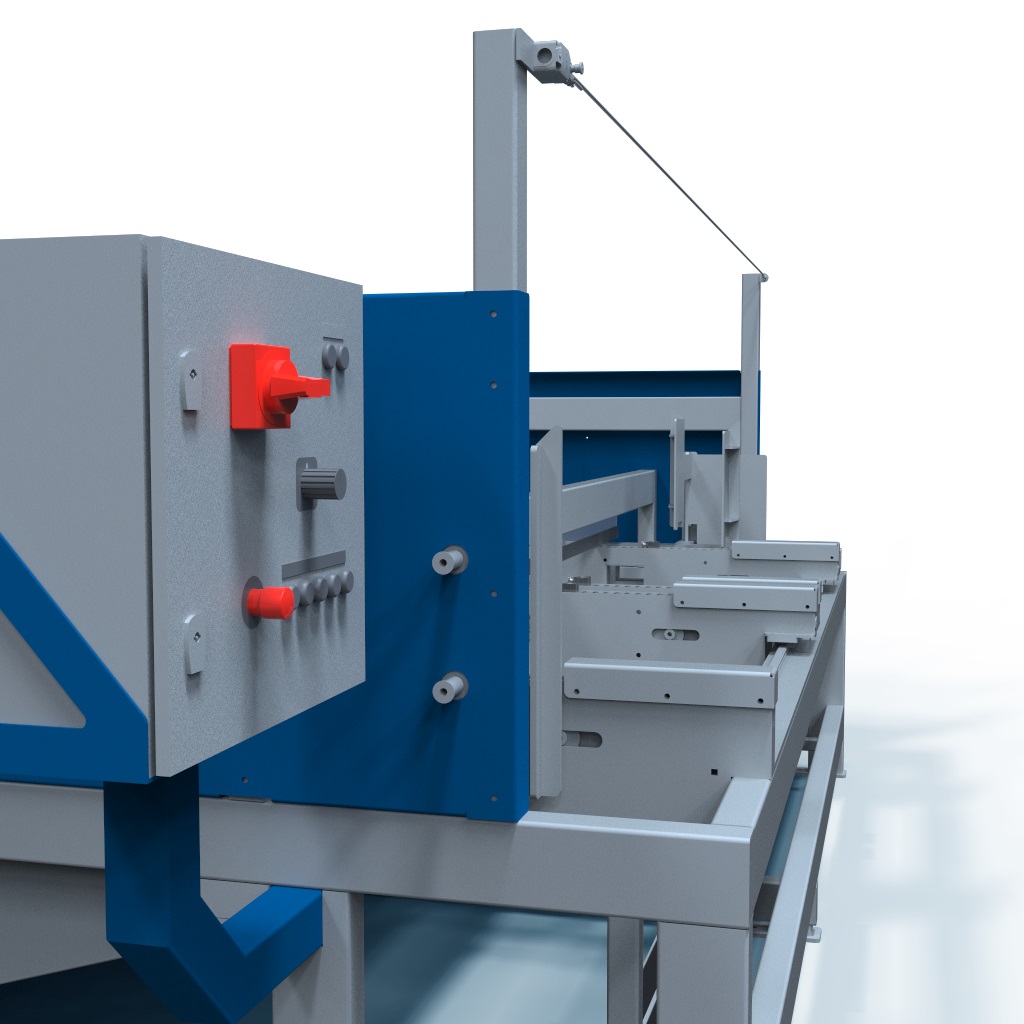

The FDR trim saw is a stationary machine designed for the transverse cutting of boards using circular saws. Depending on the model, it can feature between 2 to 6 cutting supports, each equipped with an electric motor. The circular saws are mounted on the shafts of these motors for efficient operation.

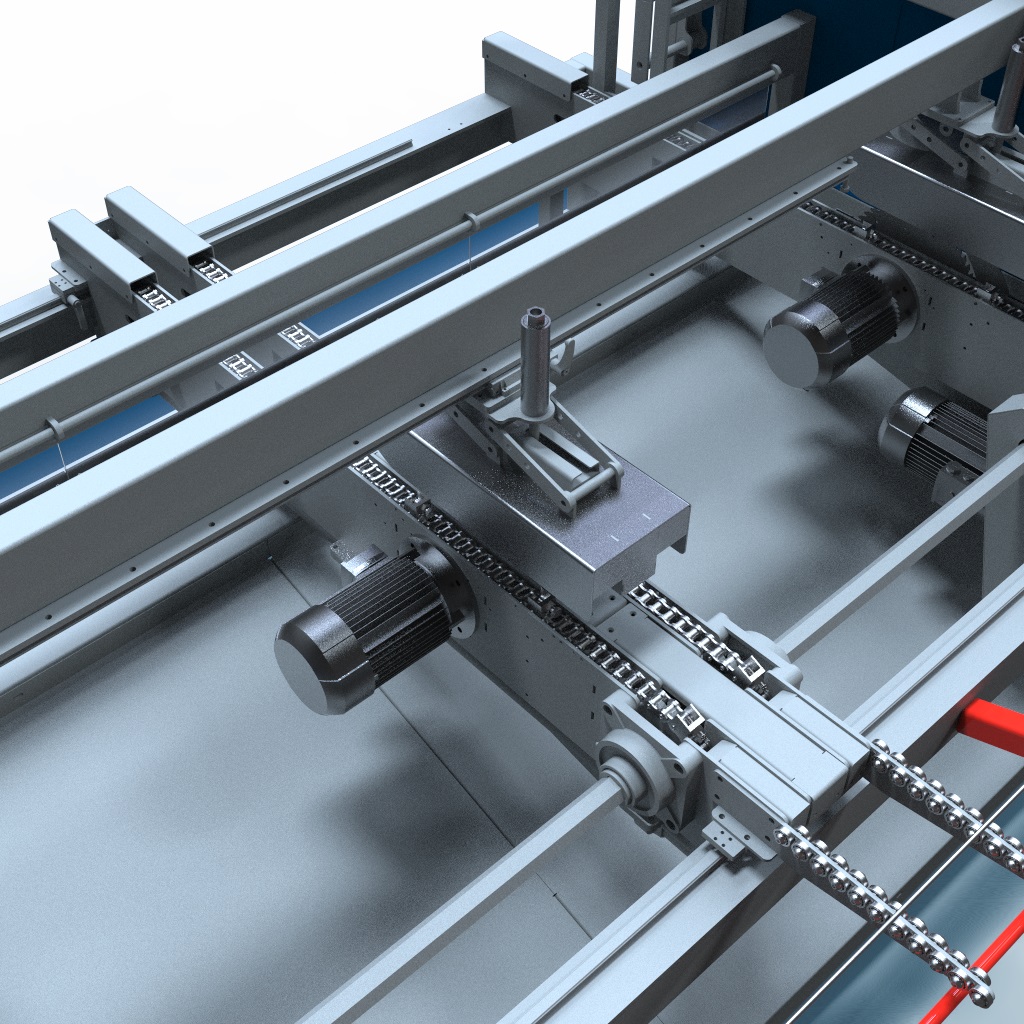

The spacing between the circular saws is manually adjusted using a crank and a toothed gear connected to the cutting supports. The first carriage, as viewed from the control panel, is a fixed element and cannot be moved.

The processed material is fed by a chain conveyor with drivers, powered by an electric motor through a worm gear.

Raw material is manually loaded into the tray at the start of the feeding zone. From there, the feed mechanism’s drivers select each board individually and move it towards the cutting zone. After cutting, the boards are transported to the collection area.

Additional equipment:

- Receiving table

- Waste conveyor belt

- Transverse wood feeder

| Data | Value |

|---|---|

| Length | 1900 mm |

| Width | 1400 mm |

| Height | 2800 mm |

| Data | Value |

|---|---|

| Length of the finished board | 1600/2500/4100/6100 |

| Number of saws | 2/3/4/5/6 |

| Min.length of the finished board | 500 mm |

| Width of the finished board | 230 mm |

| Board thickness | 55 mm |

| Circular saw diameter | 350 mm |

| Spindle diameter | 40 mm |

| Data | Value |

|---|---|

| Feed motor power | 1.6 kW |

| The rotational speed of the saws | 2900 rpm |

| Smooth feed regulation | 0-18 m / min |

| Data | Value |

|---|---|

| Spindle motors power | 2,4 lub 3,2 kW |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472