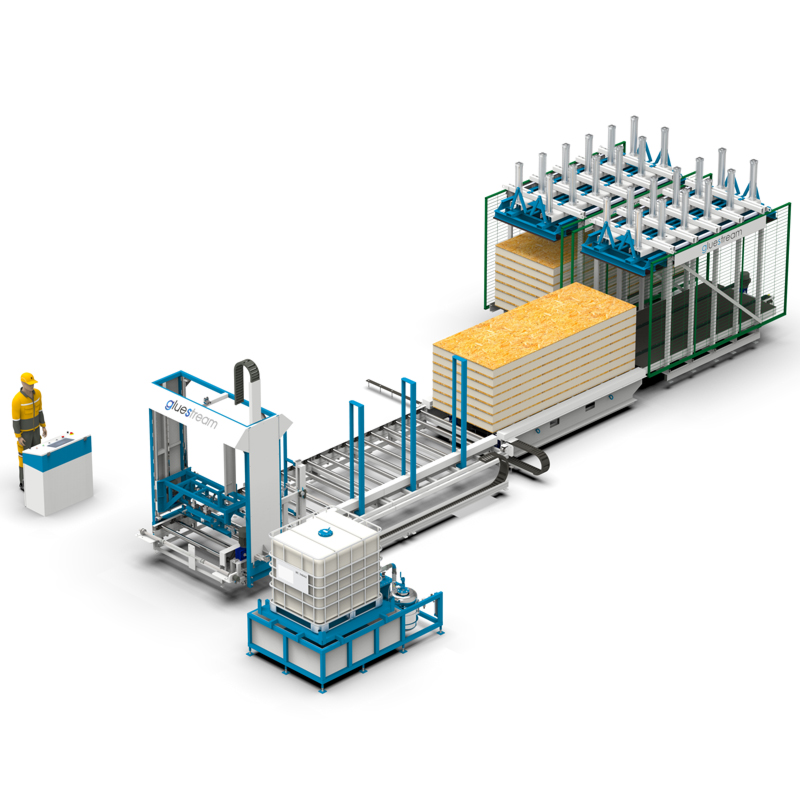

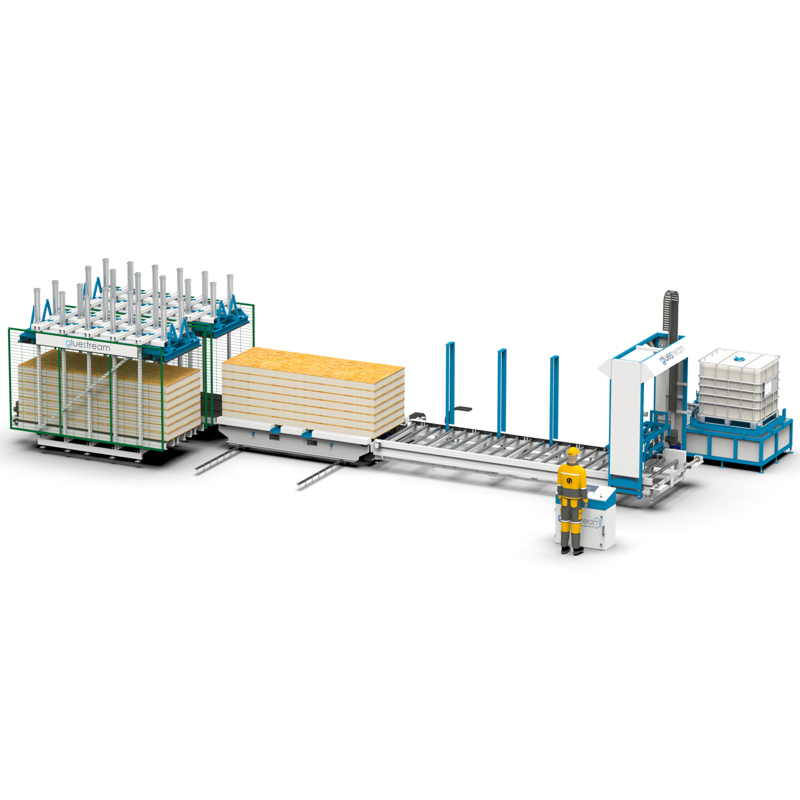

ASPL – 10M Automatic SIPs Production Line

Automatic SIPs manufacturing line

The ASPL-10.M is specifically designed for the automatic manufacturing of SIPs (Structural Insulated Panels) sandwich panels. This comprehensive production line comprises several key components, including:

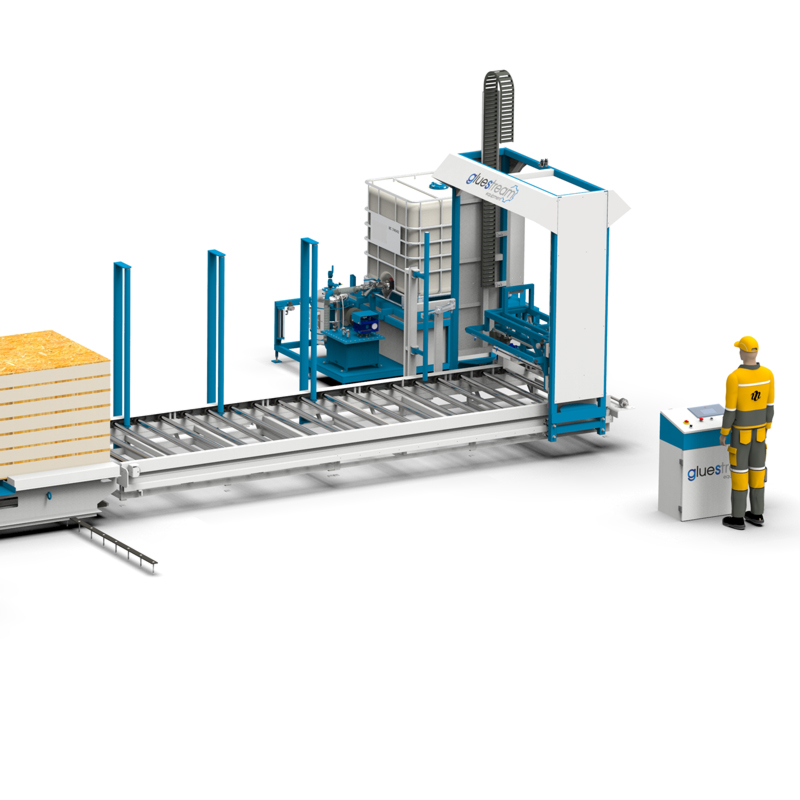

- Portal Type Mobile Adhesive Extruder SPL-10M: Ensures precise adhesive application, enhancing the bonding process in SIPs manufacturing.

- Motorised Automatic Roller Conveyor: Facilitates smooth movement of materials, thus increasing efficiency.

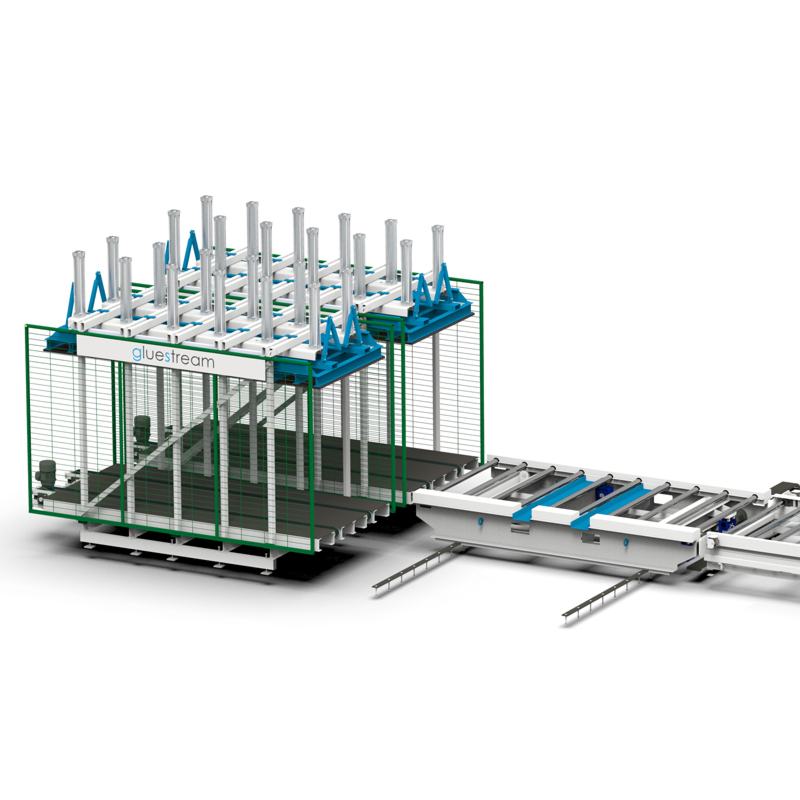

- Automatic Distribution Platform: Streamlines the workflow, allowing for seamless integration into the SIPs production line.

- Press Station: This consists of multiple P-type presses, each equipped with a motorised roller conveyor to ensure effective compression of the panels.

- Control Cabinet: Built on a reliable Siemens controller for consistent operation.

- Glue Pump Station: Guarantees a steady supply of adhesive throughout the SIPs manufacturing process.

Notably, this SIPs production line is engineered to glue various materials, including metals, PVC sheets, OSB boards, MgO boards, fibre-cement boards, particleboards, and more, with an array of core materials such as expanded polystyrene, extruded polystyrene, polyurethane (PU), and mineral wool.

Innovative Adhesive Applicator for Enhanced Performance

The KAM-PRO series adhesive applicator features two-way pneumatic valves and a specialised tray filled with a plasticiser. This design effectively prevents the premature adhesive reaction inside the applicator nozzles. Importantly, the shutter tray closes automatically in the event of a power failure or if the machine stops for more than one minute; this option can be adjusted according to the open time of the adhesive used. Additionally, manual closure is achievable via a designated key on the control panel.

Precision Adhesive Dosing Pumps for Optimal Application

In our machinery, we employ GLUESTREAM precision specialised adhesive dosing pumps. These pumps are crafted from high-quality metal with precision surface treatment, ensuring that radial and axial gaps between the working parts do not exceed 6 microns. Furthermore, our pumps are designed without sealing rings, gaskets, bushings, or bearings, making them exceptionally durable. Dosing rate adjustments are managed by frequency converters; thus, when the viscosity of the adhesive changes, the torque rate of the pump is automatically corrected to deliver the exact amount of glue, accounting for viscosity variations (±5 g/m²).

The adhesive is applied through jets spaced 8-10mm apart. Notably, the gluing width can be adjusted: 100mm via valves, or 10mm by simply replacing the jet cover, which can be done in under a minute. The jets are constructed from PTFE to ensure longevity. During standby periods, the adhesive jets are automatically sealed by the shutter liquid tray, preventing adhesive polymerisation.

Once the pressing of the panels is complete, they are automatically transferred to the unloading zone, where they can be easily collected using a forklift. The pump station is designed for effective adhesive feeding from the main tank to the application node, featuring a frame for IBC container installation or a 200L drum, along with chemical-resistant high-pressure pipes.

Additional Features for Enhanced SIPs Manufacturing

Moreover, the line can be equipped with Jib-Cranes, allowing operation by a single worker, which significantly enhances productivity in the SIPs production process.

All GLUESTREAM machinery is equipped with a remote access module, enabling customers to access 24/7 online support for any technical inquiries.

If you require our technical support, please do not hesitate to contact us. Our team is eager to share our extensive knowledge and experience in adhesive technology, cultivated over many years in the industry.

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472