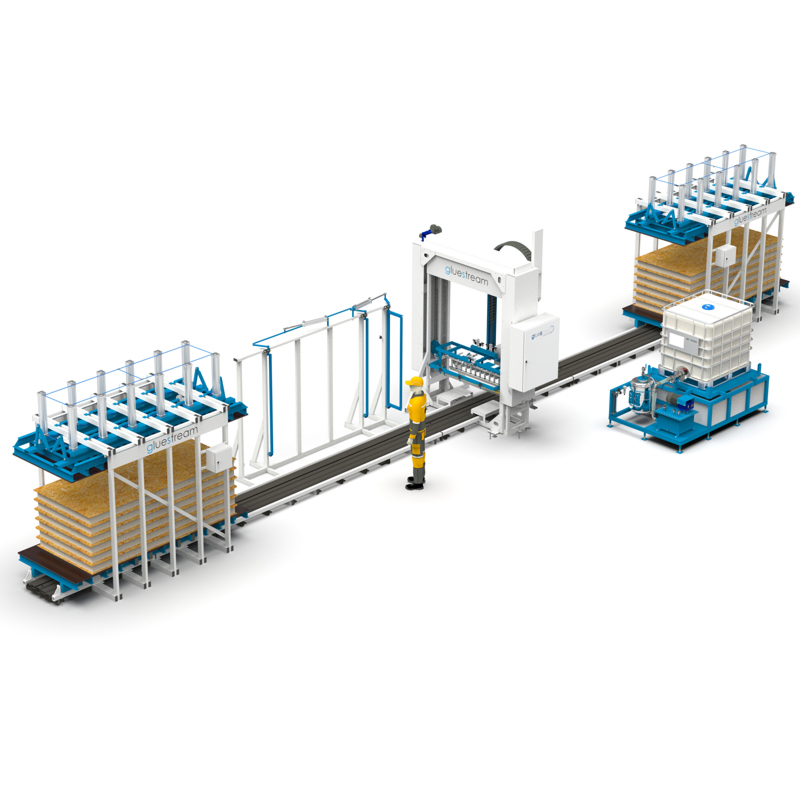

SPL- 2 Sip Panel Production Line

Structured insulated panels production line with two driven carriages and two P-type pneumatic presses

The Gluestream Sandwich Panel Production Line SPL-2 represents the quintessential solution for those aspiring to manufacture Structured Insulated Panels (SIPs) featuring a diverse array of skins and core materials. This can be achieved using either one-component or two-component PUR adhesive technology. With our superior polyurethane adhesives delivering exceptional bonding properties, we can produce SIP panels composed of various materials, including steel, wood-based boards, cement-based boards, plastic, and aluminium sheets, along with core materials such as EPS, XPS boards, foamed PU, PIR boards, and mineral wool.

Our Sandwich Panel Production Machine SPL-2 is meticulously designed to facilitate the efficient production of thin material panels, such as aluminium sheets, steel sheets, and PVC sheets, all without compromising the integrity of glue-covered materials. Furthermore, the SPL-2 machine is constructed to adhere to the latest safety standards, thereby prioritising both productivity and safety in your operations.

Gluestream, recognise the significance of high-quality products. Therefore, we are committed to offering our expertise to assist you in manufacturing the best SIPs. We invite you to get in touch with us today to discover how our SPL-1 production machine can cater to your SIP and sandwich panel production needs.

Comprehensive SIP Manufacturing Solutions

When it comes to the manufacturing of Structured Insulated Panels (SIPs), the Gluestream SPL-2 production line emerges as the ideal choice. Our state-of-the-art machinery includes an adhesive-applying portal, the GLUESTREAM SPL-10 S, complemented by two P-type pneumatic presses, a panel positioning system, and a pump station. This arrangement affords a versatile range of options for SIP panel production.

Advanced Glue-Applying System

Our glue-applying system offers options for both 1-C PUR adhesive and 2-C PUR adhesive, both of which are liquid and solvent-free. This allows for the efficient production of high-quality panels. If you opt for the 1-C PUR adhesive, please note that the delicate nature of the glue requires special attention to prevent any adhesive reaction. Fortunately, our hermetically sealed system effectively prevents any adverse reactions within the machine, while the high-precision dosing pump ensures the correct amount of adhesive is applied consistently.

Streamlined Panel Assembly and Unloading

The SPL-2 line is equipped with drives and a carriage designed to facilitate the assembly of the panel stack. Moreover, unloading slots are available to enable the easy removal of the finished product using a forklift. For those requiring additional capacity, our SIP panel manufacturing line SPL-2, which features two presses, is an excellent alternative.

Reliable Customer Support

Cibor W.M and Gluestream, believe that efficient machinery should be complemented by reliable customer support. Our remote access modules provide you with 24/7 support as needed, ensuring peace of mind and uninterrupted production.

Expert Guidance for Your SIP Production Line

If you are considering launching a SIP production line, we recommend utilising either 1-C PUR or 2-C PUR adhesives to bond materials such as steel, wood-based boards, cement-based boards, plastics, aluminium sheets, composite materials, and more. Our team of experienced engineers is on hand to offer expert guidance on the ideal customisation of equipment to meet your specific production requirements.

Contact Us Today

We invite you to contact us today to learn more about how the Gluestream SPL-2 SIP manufacturing line can elevate your production capabilities to the next level.

How to Produce SIP Panels

For detailed information on how to manufacture SIP panels and the equipment required to organise a SIPs factory, please follow the link provided.

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472