KP-900 AUTOMAT/EASY CUT Cross-Cut Saw

Automatic crosscut saw

The KP-900 Automat/Easy Cut crosscut saw is an excellent choice for preparing materials used in the production of pallets and other wooden packaging products.

KP-900 AUTOMAT/EASY CUT Cross-Cut Saw

Basic Cutting Modes

Manual Mode

You can set the length of each cut by either moving the material using the buttons on the panel or by adjusting the length on the control panel’s dial. To start the cut, simply press the button on the control board. This mode is ideal for making individual sequential cuts.

Automatic Mode

- Set a single cut dimension for the entire length of the input material. When you initiate the cut with the pedal, the entire material will automatically be cut to this specified length. Once the cut is complete, the feeder will return to the preset length for the input material. This mode is ideal for producing pallet blocks and allows for quick adjustments between different lengths during frequent material changes.

- You can also configure a combination of cut dimensions for the entire length of the input material. Pressing the pedal will automatically cut the material into these specified lengths. After the cut, the feeder resets to the input material’s preset length. The machine’s memory can store up to 10 programs, each with 10 length settings, enabling easy rewriting, editing, adding, and deleting of programs. This mode is perfect for maximizing material yield and is particularly beneficial for producing cross-sections for various packaging products. In automatic mode, you can also set automatic front and rear trims.

Sturdy and solid construction with a robust cover

in the cutting area ensures high work safety.

Material Flow

In the basic configuration, the saw has a LEFT orientation, meaning the material flow is from right to left.

The quality of individual components, materials, and processing

Ensures trouble-free operation and long life in demanding working conditions.

Safety features in the basic equipment

Include an electronic packet guard to prevent material collisions with the upper pressure system, along with an end flap featuring a safety switch to avoid unintended material ejection beyond the operator’s reach. Emphasis is placed on features that protect both the operator from injury and the machine from damage.

Automatic Loading System

The automatic loading system is included in the standard configuration of the KP-900 AUTOMAT/EASY CUT crosscut saw. It features a pushing device that operates along a precise linear rail with bearings, ensuring durability and accurate positioning of the workpiece for cutting.

Integrated Side and Top Pressure

Ensures the secure fixation of the material during cutting, both to the work table and the rear support. This guarantees precise, perpendicular cuts without any unintended movement of the material.

Clear LCD Touch Display

Enables easy and comfortable machine control. The individual control elements are well-visible, reduce operator eye strain, and provide a perfect overview. Maximum ergonomics and the designed software ensure complete control over the machine.

Work Table at the Input Before Cutting

Facilitates easy and comfortable machine operation. The individual control elements are clearly visible, minimizing eye strain for the operator and offering an excellent overview. Optimal ergonomics and the intuitive software ensure full control over the machine.

Basic Fixed Table at the Output After Cutting

This standard table measures two meters in length and features partial coverage in the cutting area. The operator can safely remove the cut material without the risk of encountering cut-offs, chips, or injury from the cutting disc. The table has an 8° tilt, but if the saw is equipped with a cross-loading conveyor at the input, the table tilt is adjusted to 0°.

KP-900 AUTOMAT/EASY CUT Cross-Cut Saw

The Optimization Saw KP-900 Automat/Easy Cut is designed for precision cutting in production, minimizing waste of costly materials while maximizing speed and ensuring workplace safety. Its key advantage is the high flexibility in both input and output dimensions of the processed materials. The saw operates intuitively, with specialized software that simplifies programming and entering cutting parameters. The KP 900 EasyCut also provides enhanced options for mechanization at the output.

Device Functions

Length Optimization

This function minimizes waste and maximizes yield for the assortment. The material is optically scanned by a scanner and automatically arranged for cutting according to the specified lengths in the selected program. The optimization system prioritizes cutting the longest specified length that fits the inserted material. The saw automatically measures the length of each piece, eliminating the need for pre-sorting by size. In cases of marked defects, the material is optically divided into individual sections (from defect to defect), and these sections are then length-optimized. If a cut piece does not meet the minimum length in the program, it is discarded. Additionally, automatic front and rear trimming can be configured in the selected program.

Quality Optimization – Waste

The core of this function involves the operator visually inspecting the cut piece and marking the areas with defects that need to be removed using special chalk to draw two perpendicular lines. A scanner equipped with specialized optics then passes over the marked material, recording the positions of the necessary cuts. The resulting sections of varying lengths (from defect to defect) are automatically optimized and cut to the desired dimensions according to the cutting program via the software. If a piece does not meet the minimum length specified in the program, it is discarded. Additionally, the selected program allows for the configuration of automatic front and rear trimming.

KP-900 AUTOMAT/EASY CUT Cross-Cut Saw

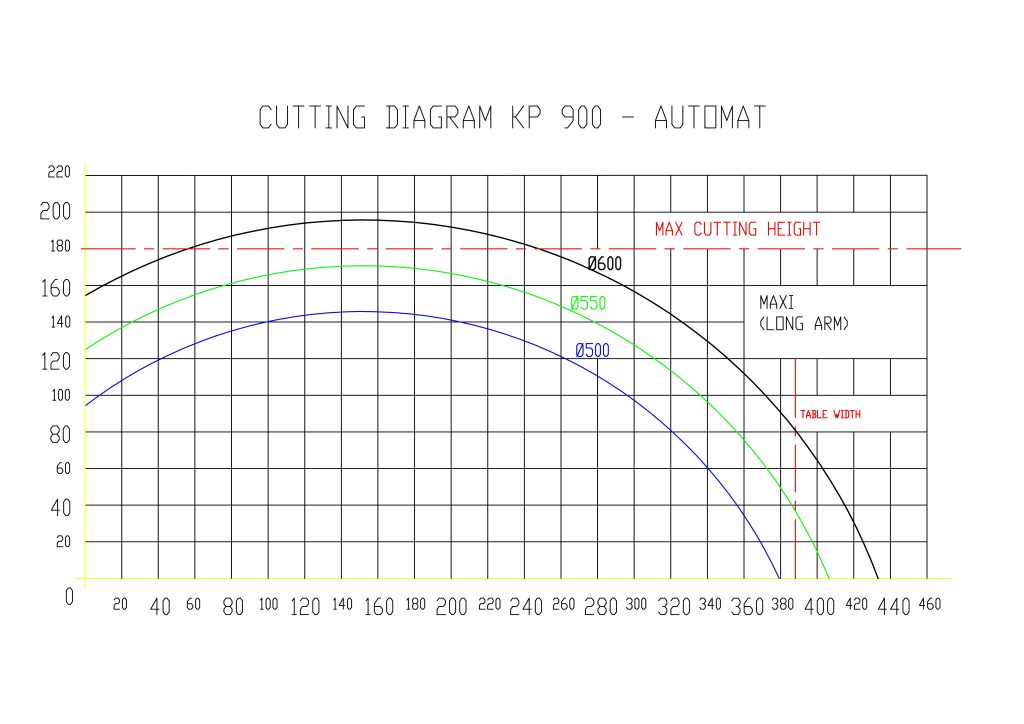

Cutting Diagram

Optional equipment

Störi Mantel automatic crosscut saws can be enhanced or customized with a variety of optional equipment. Here, we showcase the basic options, but if you have specific needs or inquiries, we would be delighted to discuss them with you.can be complemented or configured with a wide range of optional equipment.

Saw

- Right-hand configuration – material flow is from left to right.

- More powerful motor – the saw can be equipped with an 15 kW or 22 kW motor.

- Saw blade of a different diameter – optionally, the saw can be fitted with a 550 mm diameter blade.

- Lifting feeder – pneumatic or mechanical lifting of the feeding arm above the placed material when the feeder returns to the restart position.

- Special Model – simplifies the shortening of low-quality material. The operator checks and visually evaluates each piece at the input, choosing lengths using special added buttons in the cutting scheme. The modified feeder with automatic length measurement then measures the material, and the saw cuts it according to the input.

Cutting Conditions

- Finger pressure guide – increases the accuracy and perpendicularity of the cut. Presses the material against the support during cutting, preventing unintended movement during the cut.

- Side pressure guide at the output – useful where long pieces are shortened. The pressure guide increases the accuracy and perpendicularity of the cut.

Mechanization at the Input

- Cross-chain feed conveyor – can be 1 or 2 meters long. The number of conveyor arms is determined by the length of the saw’s input table and can be customized according to customer preferences.

Mechanization at the Output

- Extension of the basic fixed output table (smooth)

- Output fixed table with rollers – facilitates the easy handling of long and heavy material.

- Driven or non-driven roller conveyor – can be up to 4 meters long and 400 mm wide.

- Automatic ejector with inclined collecting table (gravity chutes) – simplifies the sorting of shortened material. Automatic saws can have up to two ejectors.

- Rake conveyor for cutoffs or blocks.

Special Equipment

- Heating of the electrical distribution panel and control panel – necessary if the machine is located in unheated spaces.

| Data | Value |

|---|---|

| Length of the entry table | 3,2 – 7,2 m |

| Tilting the input table | 8° |

| Saw Orientation | left Option: right |

| Cross table extension | yes-short Option: yes – chains |

| Fixed table | 2 m Option: Optional extension |

| Mechanization at the output | – Option: Optional |

| LCD touch screen | 8″ |

| Start of the cutting cycle | pedal |

| Cutting accuracy | +/- 0.5 mm |

| Feed rate | Continuous regulation |

| Disc diameter | 550 mm Option: 500 mm |

| Inner diameter of the clamping hole | 80 mm |

| Propulsion | AC servo |

| Loader speed | max. 1 m/s |

| Performance | 7,5 kW Option: 11 kW, 15 kW |

| Dust extraction | 2x Ø 120 mm – 30 m/s |

| Compressed air | pressure min. 0.6 Mpa |

| Capacitive air consumption | 250 l/min. |

| Voltage | ~3×400 V/50Hz |

| Data | Value |

|---|---|

| Length of the entry table | 3,2 – 7,2 m |

| Tilting the input table | 8° |

| Saw Orientation | left Option: right |

| Fixed table | 2 m Option: Optional extension |

| Mechanization at the output | – Option: Optional |

| LCD touch screen | 15″ |

| Start of the cutting cycle | pedal |

| Cutting accuracy | +/- 0.3 mm |

| Feed rate | Continuous regulation |

| Disc diameter | 600 mm Option: 550 mm |

| Inner diameter of the clamping hole | 80 mm |

| Propulsion | AC servo |

| Loader speed | max. 1 m/s |

| Performance | 7,5 kW Option: 11 kW, 15 kW |

| Dust extraction | 2x Ø 120 mm – 30 m/s |

| Compressed air | pressure min. 0.6 Mpa |

| Capacitive air consumption | 250 l/min. |

| Voltage | ~3x400V/50Hz |

We work with 30 suppliers

Interested in this product?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Looking to finance your new machine?

It couldn’t be simpler, thanks to our partnership with Venture Asset Finance. It’s a fast and secure way for your new machine to start generating income!

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472