SIP production

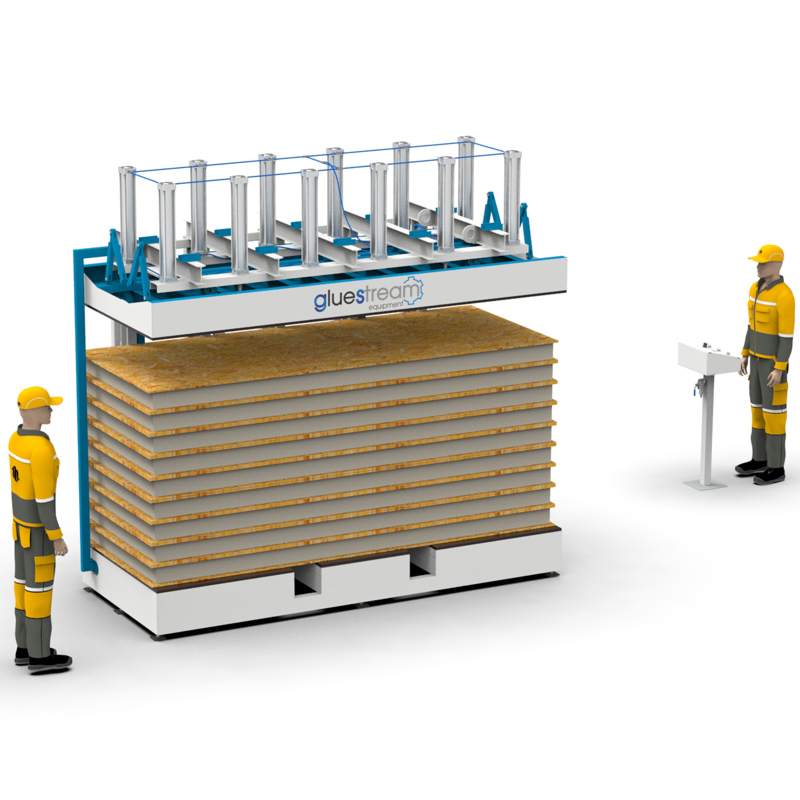

P-Type Pneumatic Press

The P-type pneumatic press is specifically designed for pressing various types of sandwich panels within the gluing technology, particularly when a high pressing force is not required. This versatility makes it an excellent choice for diverse manufacturing needs.

Read more

C-Type Pneumatic Press

The C-type pneumatic press, featuring a side-opened loading zone, is specifically designed for pressing various types of sandwich panels within the SIP panel gluing technology, particularly when a high pressing force is not required. This press is ideal for SIP manufacturing, especially when bonding hard materials with foamed materials.

Read more

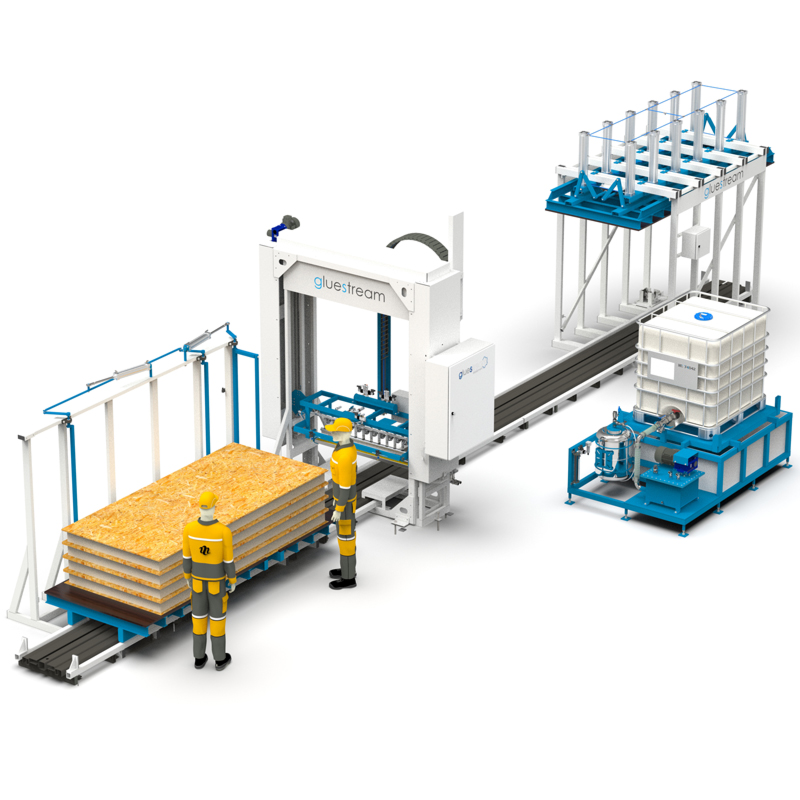

SPL- 2 Sip panel production line

The Gluestream Sandwich Panel Production Line SPL-2 represents the quintessential solution for those aspiring to manufacture Structured Insulated Panels (SIPs) featuring a diverse array of skins and core materials. This can be achieved using either one-component or two-component PUR adhesive technology. With our superior polyurethane adhesives delivering exceptional bonding properties, we can produce SIP panels composed of various materials, including steel, wood-based boards, cement-based boards, plastic, and aluminium sheets, along with core materials such as EPS, XPS boards, foamed PU, PIR boards, and mineral wool. Our Sandwich Panel Production Machine SPL-2 is meticulously designed to facilitate the efficient production of thin material panels, such as aluminium sheets, steel sheets, and PVC sheets, all without compromising the integrity of glue-covered materials. Furthermore, the SPL-2 machine is constructed to adhere to the latest safety standards, thereby prioritising both productivity and safety in your operations.

Read more

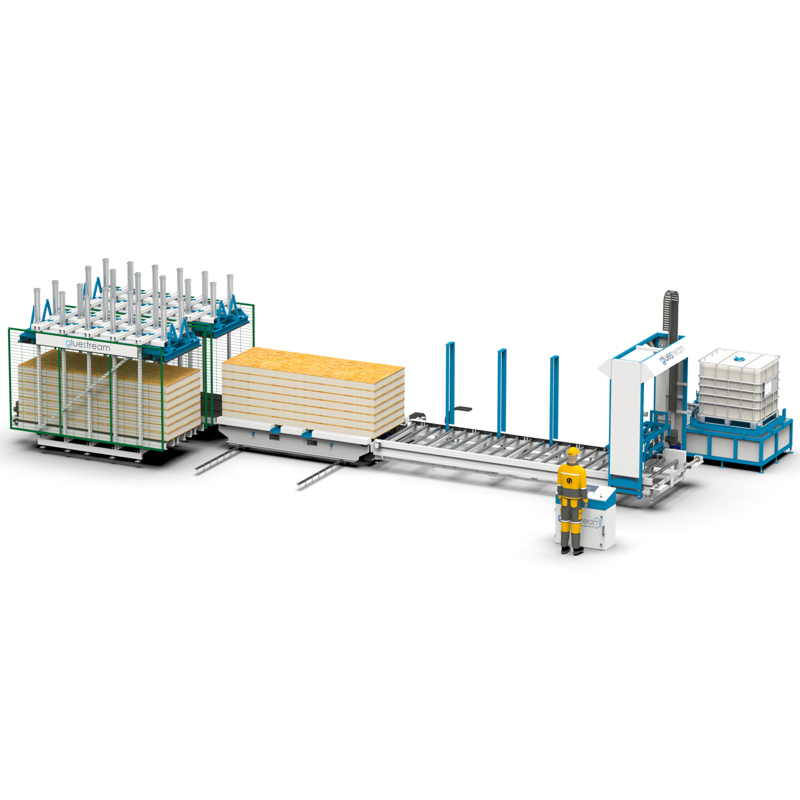

SPL- 1 Sip panel production line

The Gluestream Sandwich Panel Production Line SPL-1 is the ideal solution for anyone looking to manufacture structured insulated panels (SIPs) with a variety of skins and core materials. Our technology accommodates both one-component and two-component PUR adhesive options, ensuring versatility in your production process. With our superior polyurethane adhesives, which provide exceptional bonding properties, you can create SIP panels using a diverse range of materials. These include steel, wood-based boards, cement-based boards, plastic, and aluminium sheets, complemented by core materials such as EPS, XPS boards, foamed PU, PIR boards, and mineral wool. Efficient Production of Thin Material Panels Our sandwich panel production machine, the SPL-1, is meticulously designed to produce thin material panels, such as aluminium sheets, steel sheets, and PVC sheets, with utmost efficiency. Importantly, this machine operates without compromising the integrity of the glue-covered materials. Built to adhere to the latest safety standards, the SPL-1 prioritises both productivity and safety.

Read more

SPL- 9.1C PUR glue applicator

We are excited to present the Gluestream SPL-9.1C.PUR, an innovative and automated single-component PUR (1-C PUR) glue-applying machine specifically designed for the manufacturing of a variety of sandwich panels. Thanks to its versatile design, the SPL-9 can be employed on either a stationary platform or a movable platform, featuring options for both manual and electric drive systems. Why Choose 1-C PUR Technology? You may wonder what sets 1-C PUR technology apart. This humidity-reactive adhesive boasts exceptional bonding properties, making it an ideal solution for a range of materials, including plastics, metals, aluminium, OSB, MGO, plywood, fiberglass, fibre cement boards, plasterboards, EPS, XPS, PIR, PUR boards, stone wool, wood wool, and many others. Notably, this type of adhesive is extensively used in SIPs manufacturing and can be tailored for fully automated SIPs production lines.

Read more

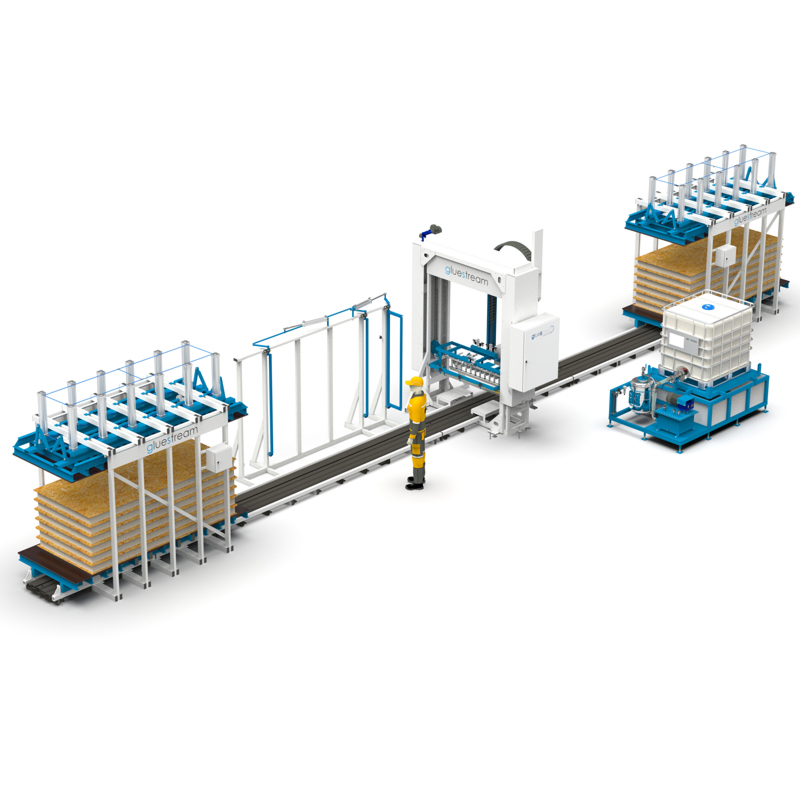

ASPL – 10M Automatic SIPs Production Line

The ASPL-10.M is specifically designed for the automatic manufacturing of SIPs (Structural Insulated Panels) sandwich panels. This comprehensive production line comprises several key components, including: Portal Type Mobile Adhesive Extruder SPL-10M: Ensures precise adhesive application, enhancing the bonding process in SIPs manufacturing. Motorised Automatic Roller Conveyor: Facilitates smooth movement of materials, thus increasing efficiency. Automatic Distribution Platform: Streamlines the workflow, allowing for seamless integration into the SIPs production line. Press Station: This consists of multiple P-type presses, each equipped with a motorised roller conveyor to ensure effective compression of the panels. Control Cabinet: Built on a reliable Siemens controller for consistent operation. Glue Pump Station: Guarantees a steady supply of adhesive throughout the SIPs manufacturing process. Notably, this SIPs production line is engineered to glue various materials, including metals, PVC sheets, OSB boards, MgO boards, fibre-cement boards, particleboards, and more, with an array of core materials such as expanded polystyrene, extruded polystyrene, polyurethane (PU), and mineral wool.

Read moretutaj

We work with 30 suppliers

How can we help you?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472