Panel & Beam Saws

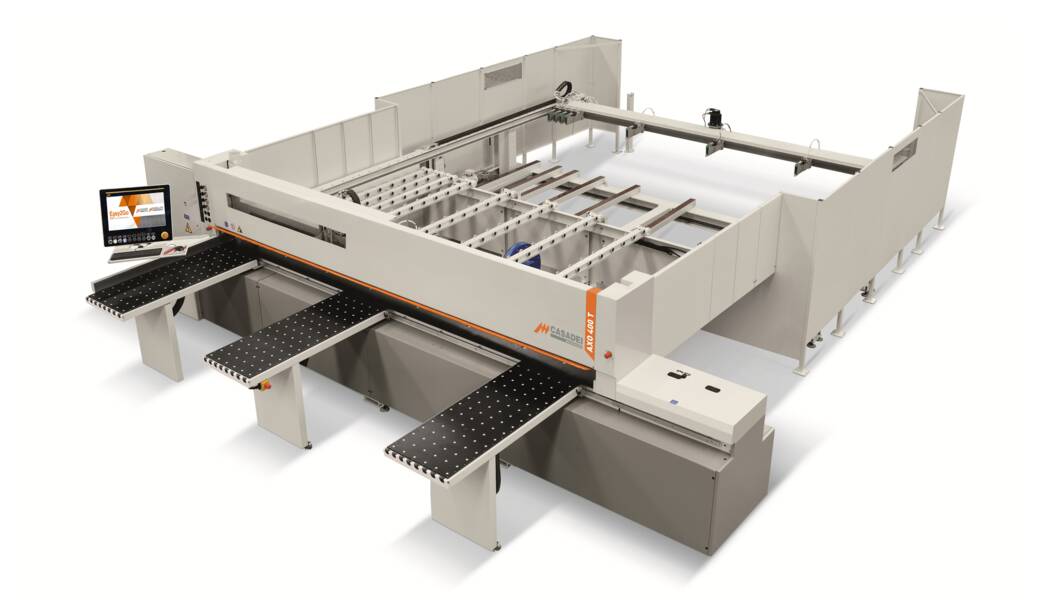

AXO 400 T – AXO 500 T HD

To handle high production rates, we offer Casadei’s two models of panel saws with a rear loading table: the AXO 400 T and the AXO 500 T HD. Designed for efficiency and precision, these saws are ideal for busy woodworking operations. The AXO 400 T features a robust construction and user-friendly controls, making it perfect for versatile cutting tasks. Meanwhile, the AXO 500 T HD provides enhanced power and advanced features for even more demanding applications. Both models ensure smooth material handling and quick setup, allowing businesses to maximize productivity while delivering high-quality results. With Casadei’s reliable technology, you can optimize your production processes with confidence.

Read more

AXO 400 – AXO 500 HD

The AXO 400 and AXO 500 HD are advanced automatic horizontal beam saws designed for high production rates. Both models feature robust construction and cutting-edge technology for durability and reliability in busy woodworking environments. The AXO 400 strikes a balance between performance and versatility, with a powerful motor and efficient blade projection for precise cuts across various materials. Its user-friendly interface allows for quick adjustments, maximizing workflow efficiency. In contrast, the AXO 500 HD is built for the most demanding production needs. Its exceptional sturdiness, impressive blade projection, and high-speed capabilities enable rapid processing of large panel stacks, significantly reducing cycle times and enhancing overall productivity.

Read more

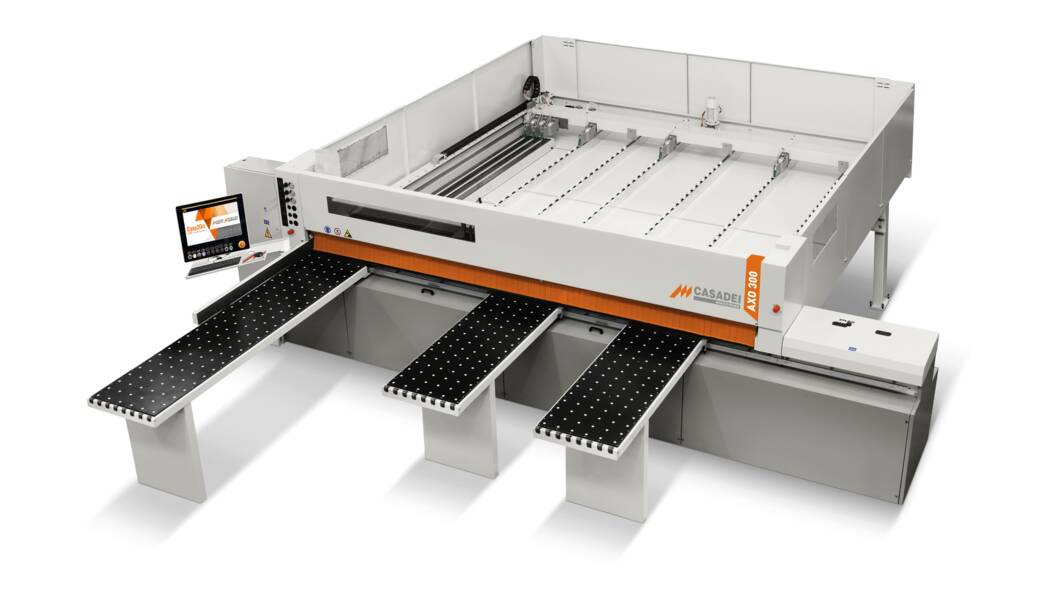

AXO 300

The AXO 300 automatic horizontal beam saw is powerful and reliable, delivering perfect dimensional precision in every finished product. Designed for efficiency, it features advanced technology that allows for smooth, accurate cuts across a variety of materials. Its user-friendly interface ensures quick adjustments, optimizing workflow and minimizing downtime. Built with robust materials, the AXO 300 provides long-lasting durability, making it suitable for both small workshops and large-scale operations. Whether you need intricate designs or high-volume production, this saw consistently meets the demands of any woodworking project.

Read more

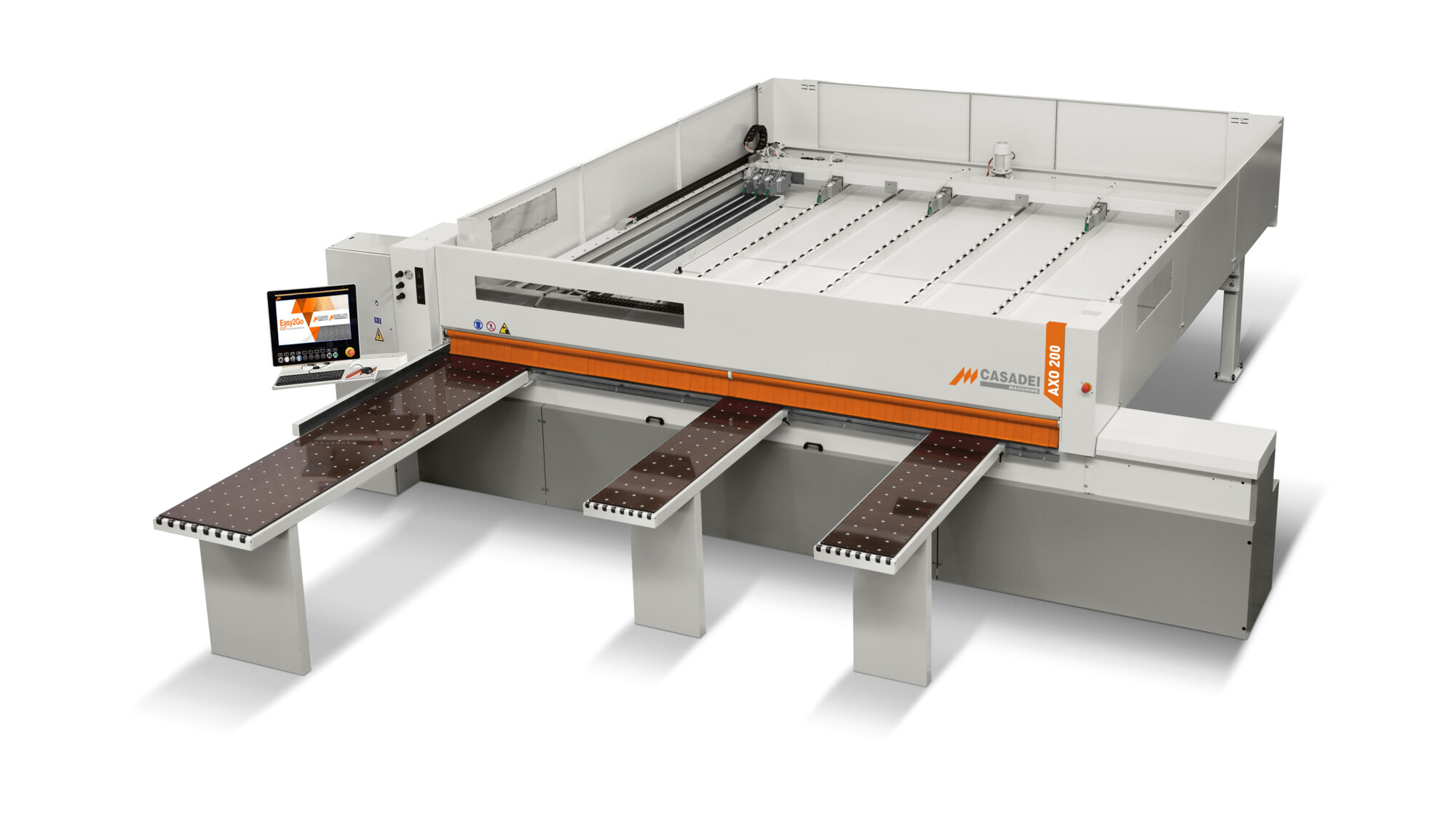

AXO 200

The new AXO 200 automatic horizontal beam saw seamlessly combines power, reliability, and functionality in a compact design. Despite its small size, it delivers impressive cutting performance, making it ideal for workshops with limited space. Engineered for precision, the AXO 200 features advanced technology that ensures accurate cuts across various materials. Its user-friendly interface allows for easy adjustments, enhancing workflow efficiency. Built with robust components, this machine is designed to withstand demanding production environments while maintaining consistent quality. Whether for small-scale projects or intricate designs, the AXO 200 is a versatile solution for modern woodworking needs.

Read more

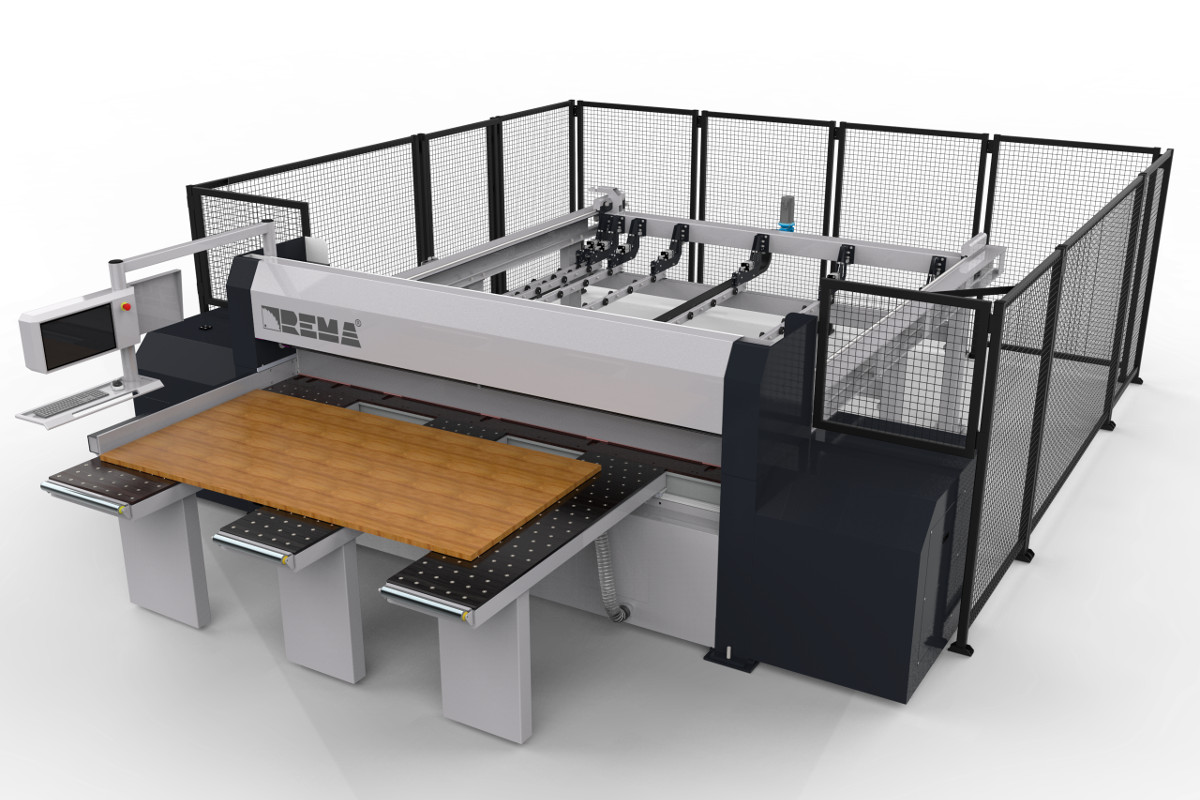

FOX 3200

Introducing the latest addition to our lineup: the REMA Fox 3200 panel saw! This cutting-edge machine is engineered for exceptional precision and efficiency, making it perfect for a wide range of woodworking applications. With its sturdy construction and advanced technology, the REMA Fox 3200 ensures clean, accurate cuts, whether you’re working with large panels or intricate designs. Its user-friendly interface and versatile features allow for seamless operation, boosting productivity in any workshop. Elevate your woodworking capabilities with the reliability and performance of the REMA Fox 3200!

Read more

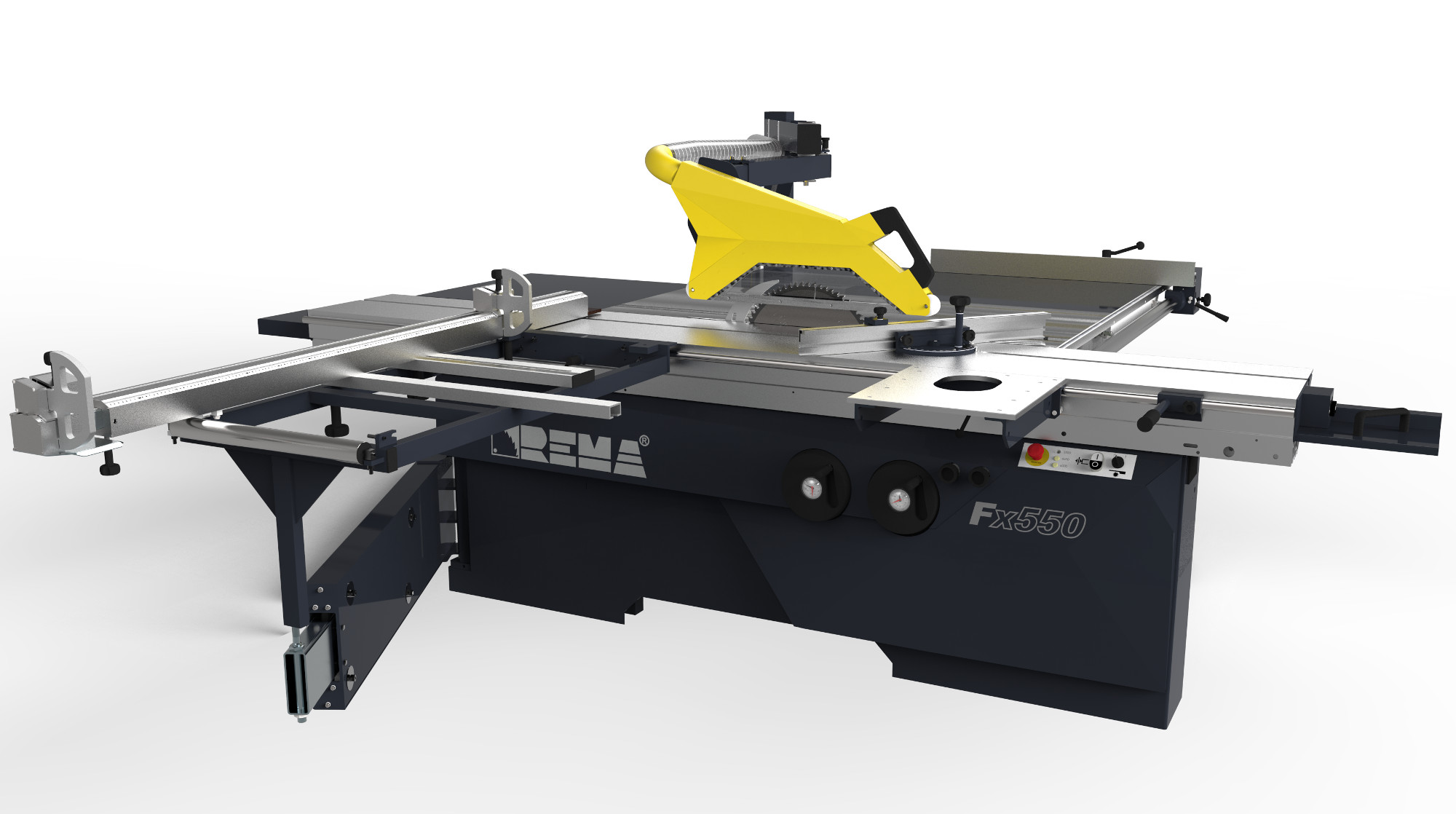

Fx500

The REMA Fx500, is a cutting-edge sliding table panel saw that sets the benchmark for its category. It boasts a robust construction and a wide range of cutting capabilities, making it ideal for both professional and industrial use. Designed with precision in mind, the Fx500 ensures accurate cuts every time, enhancing productivity and efficiency in the workshop. Its user-friendly interface and advanced features, such as adjustable cutting angles and easy-to-navigate controls, make it accessible for operators of all skill levels. Additionally, the saw’s durable materials and engineering provide long-lasting performance, reducing the need for frequent maintenance. With the Fx500, users can expect not only exceptional quality but also the versatility to tackle various materials and project requirements, ultimately elevating their craftsmanship to new heights.

Read more

Fx400

The Rema Fx400 is a versatile panel saw designed to perform all essential functions for cutting boards, solid wood, and wood-based materials. It features a drive unit that accommodates circular saw blades with diameters ranging from Ø300 to Ø400 mm, providing a maximum sawing height of 97.5 mm when using the undercutter. The standard cutting width with the longitudinal ruler is 1050 mm, with an optional width of 1300 mm. The Fx400 comes with a standard moving table length of 3000 mm, with additional options available in 2000 mm, 2500 mm, and 3200 mm lengths.

Read more

Fx350

The REMA Fx350 is a sliding table panel saw that meets all the essential requirements for effectively cutting wood-based boards. Designed for precision and efficiency, it features a robust construction that ensures stability during operation. This saw is equipped with advanced features that enhance cutting accuracy, making it suitable for both professional and industrial use. With its user-friendly interface and reliable performance, the Fx350 is an ideal choice for those looking to achieve high-quality results in their woodworking projects

Read moreBeam Saws and Panel Saws are essential tools for modern woodworking, and at Cibor Woodworking Machinery, we provide the best solutions for professionals and hobbyists. Our range of Beam Saws and Panel Saws combines accuracy, efficiency, and reliability, making them a must-have in any workshop.

Beamsaws

Beam Saws are perfect for cutting large panels of wood, MDF, or other materials with precision. Our Beam Saws are equipped with advanced features, such as automated positioning systems, durable blades, and high-speed motors, ensuring smooth, accurate cuts even in demanding environments. Whether you need high-volume production or custom designs, our Beam Saws deliver exceptional performance, optimizing productivity while maintaining top-tier precision. Popular among furniture manufacturers and carpentry workshops, they are the ideal choice for professionals seeking high performance.

Panel Saws

For versatility, our Panel Saws are the ideal option. These saws are perfect for cutting panels into various shapes and sizes with ease and accuracy. With ergonomic designs, easy-to-use controls, and durable construction, Panel Saws can handle even the toughest tasks. From straight cuts to intricate patterns, these saws offer flexibility for a wide range of applications, including cabinetry, joinery, and custom woodworking projects.

At Cibor Woodworking Machinery, we offer high-quality beamsaws and panelsaws that meet the needs of the woodworking industry. Designed for durability, precision, and efficiency, our machines are built to enhance your workflow and deliver consistent results.

Explore our full range of Beam Saws and Panel Saws today and discover how our products can elevate your woodworking projects. Contact us to find the perfect machine for your workshop.

We know machinery is a big investment, so we’ve teamed up with Venture Asset Finance to offer custom financing options. Whether you need one machine or an entire production line, we can help you get the funding you need.

Contact us today to learn more!

We work with 30 suppliers

How can we help you?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472