Sawmills with Superior Efficiency and Durability

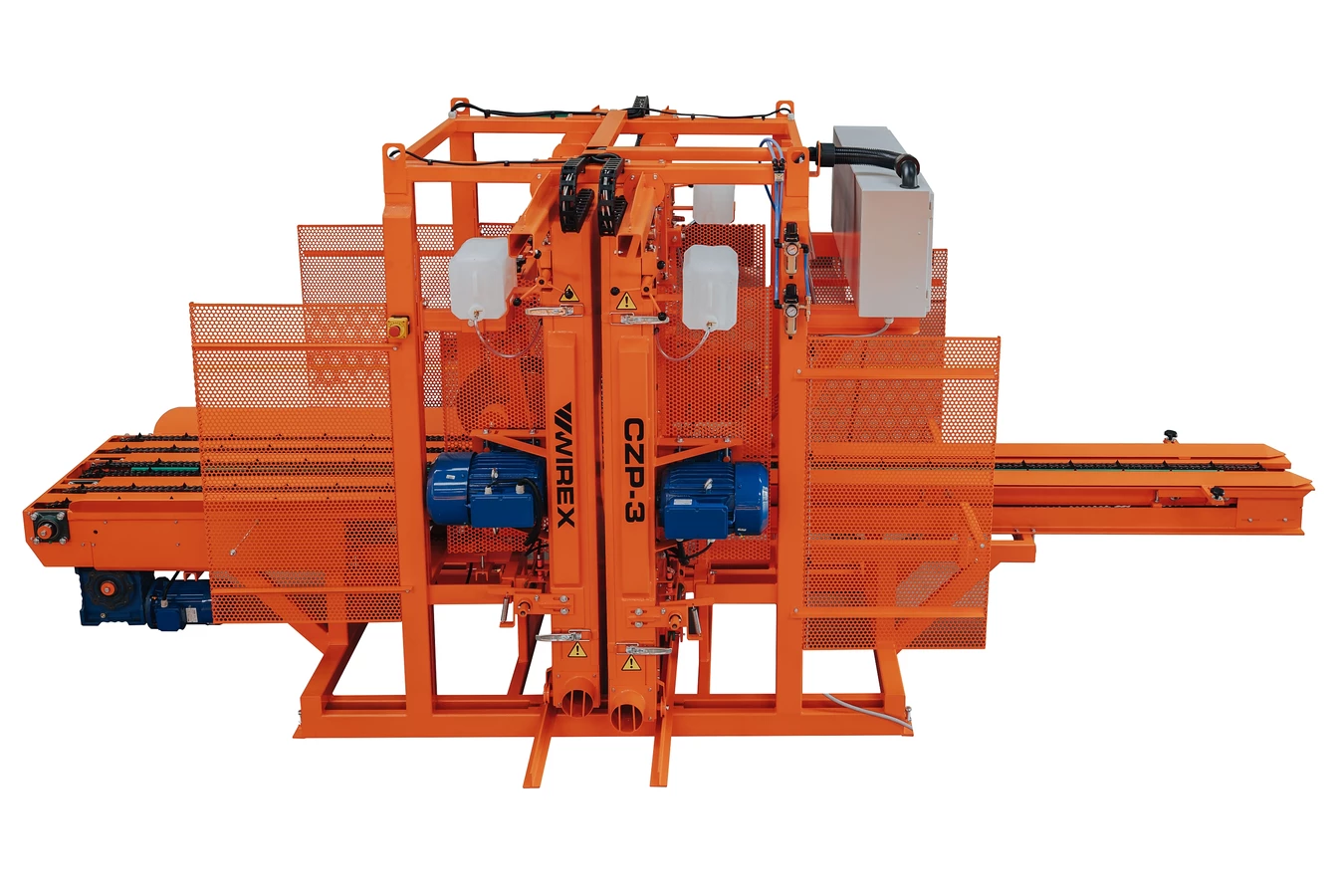

CZP-3 with Chain Conveyor

The CZP-3 with chain conveyor is designed to process thin to medium-sized logs with diameters up to 550 mm. It efficiently produces two two-sided flitches, each with a maximum thickness of 200 mm, making it ideal for various woodworking applications. The chain conveyor streamlines workflow by transporting logs smoothly through the cutting process, reducing manual handling and boosting productivity. With precision cutting capabilities, the CZP-3 ensures uniform, high-quality flitches suitable and crucial for downstream applications like furniture making and construction. Constructed for durability in mind, this sawmill can withstand the demands of daily use. Its user-friendly design allows operators to easily adjust settings for different log sizes, making the CZP-3 a valuable asset for optimizing lumber processing operations

Read more

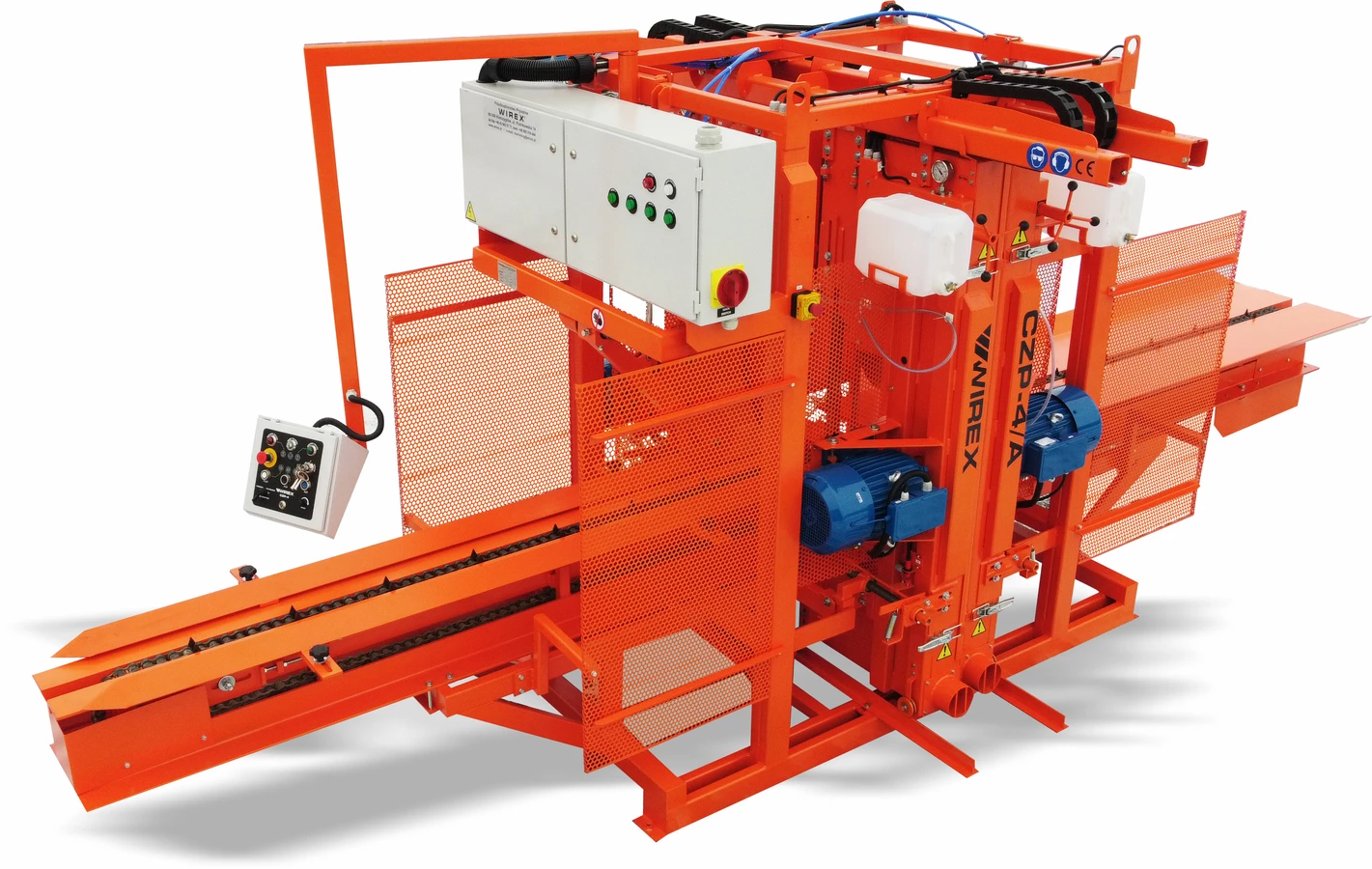

CZP-4/A with Chain Conveyor

The vertical quadruple band sawmill CZP-4/A, equipped with a robust chain conveyor, is specifically designed to process thin round wood with a diameter of up to 400 mm efficiently. This advanced sawmill offers versatility in production, allowing operators to choose between two different output configurations. In one scenario, it produces a single flitch that yields two planks along with offcuts, making it ideal for projects requiring specific dimensions and minimal waste. Alternatively, the mill can process three flitches at once, significantly increasing throughput and maximizing productivity for larger operations. With its precision cutting capabilities and user-friendly design, the CZP-4/A with chain conveyor ensures consistent quality in every cut, making it an essential tool for sawmills looking to enhance their production efficiency while maintaining high standards of craftsmanship. Additionally, the integrated chain conveyor streamlines the workflow, facilitating smooth material handling and reducing labor costs. This sawmill is a valuable investment for any wood processing facility aiming to optimize their operations.

Read more

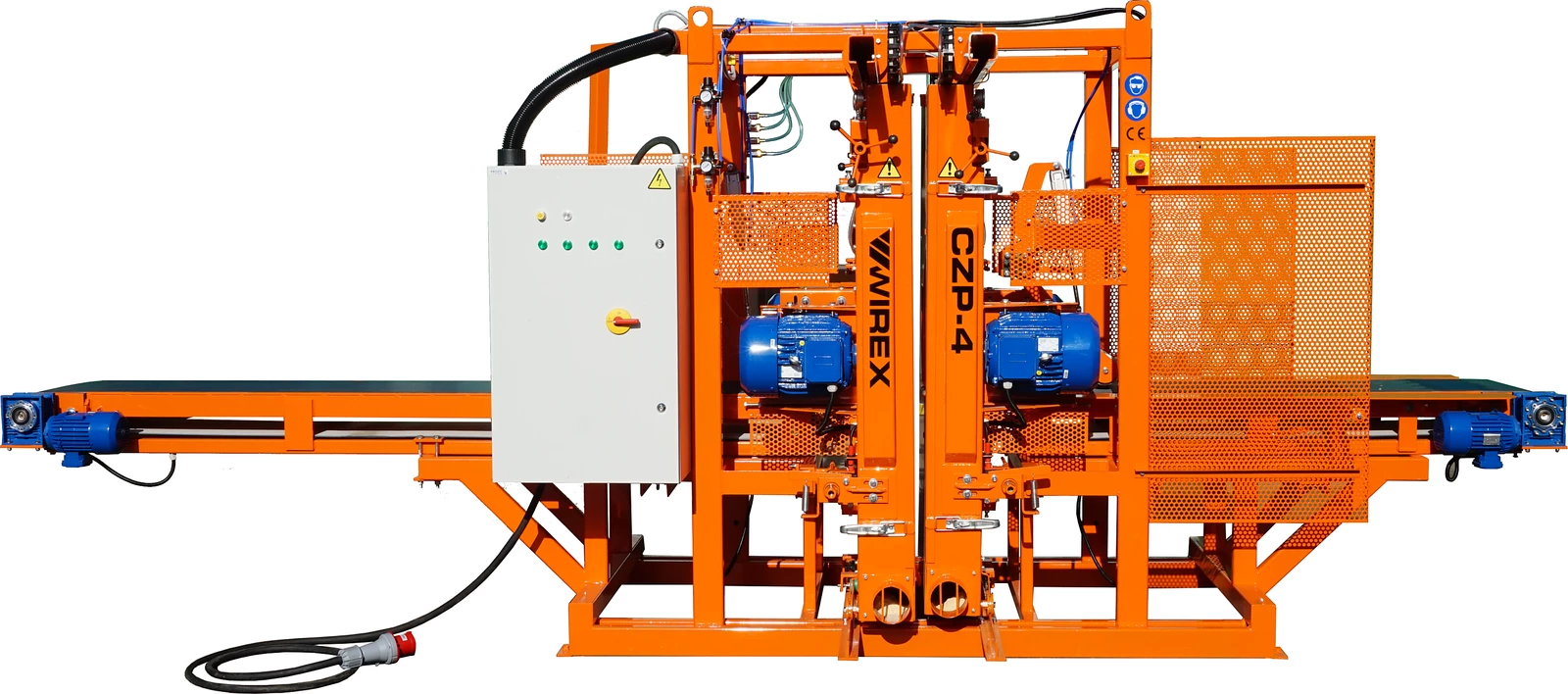

CZP-4/A WZM with Chain Conveyor

The CZP-4/A WZM with chain conveyor sawmill addresses market demands for enhanced efficiency, achieving capacities of up to 5 m³/h. By integrating material feeding and collection conveyors, output can even reach 10 m³/h, all while reducing production costs. The innovative design incorporates material feeding and collection conveyors, which not only streamline the workflow but also enhance overall output, potentially reaching an impressive 10 m³/h. This significant increase in efficiency allows sawmills to process larger volumes of wood in less time, ultimately leading to higher profitability. Moreover, the CZP-4/A WZM minimizes production costs through its optimized processes, reducing labor requirements and waste. Its user-friendly features and advanced technology ensure that operators can achieve consistent results while maintaining high standards of quality. This sawmill is an excellent investment for businesses looking to elevate their operations and stay competitive in a rapidly evolving market.

Read more

LPW Chain Conveyor

The LPW chain conveyor is expertly designed to efficiently load thin and medium-sized round wood, with specifications such as length and width tailored to meet specific customer requirements. This level of customization ensures that the conveyor fits seamlessly into your operational workflow, enhancing both functionality and productivity. This conveyor pairs perfectly with sawmill models like the CZP-2, CZP-3, and CZP-4/A, creating a cohesive system that maximizes output. Its robust construction guarantees durability and reliability, even in the most demanding environments, where consistent performance is essential for maintaining production schedules. By integrating the LPW conveyor into your operations, you can streamline the loading process, reduce labor costs, and significantly improve overall efficiency. This conveyor not only supports high productivity but also contributes to a more organized and effective sawmill operation. Additionally, its efficient design minimizes material handling time, allowing your facility to adapt swiftly to increasing production demands. With the LPW chain conveyor, you can ensure that your operations run smoothly, maintain high quality standards, and enhance workplace safety, making it an invaluable asset for any wood processing facility looking to optimize its performance and meet market challenges head-on.

Read more

CZP-4 with Belt Conveyor

The CZP-4 with belt conveyor is a sawmill engineered to efficiently process at least one-sided flitches into a diverse range of products, including pallet boards, battens, strips, square timber, and floorboards. This versatility makes it an ideal choice for various woodworking applications, allowing operators to maximize the value of their raw materials. Designed for high efficiency, the CZP-4 minimizes waste through its innovative design, which features a minimal kerf thickness. This ensures that more of the wood can be utilized, leading to cost savings and reduced environmental impact. The sawmill operates seamlessly with the belt conveyor, facilitating smooth material handling and enhancing overall productivity. In addition to its cutting capabilities, the CZP-4 with belt conveyor features user-friendly controls and robust construction, ensuring durability and reliability even in demanding production environments. Its ability to produce high-quality finished products consistently makes it an essential tool for any wood processing facility looking to enhance efficiency and output. By integrating the CZP-4 sawmill into your operations, you can streamline your production process and meet increasing market demands with confidence.

Read more

Operator’s Cabin

The operator’s cabin enhances comfort for the operator while integrating advanced electronic systems that facilitate sawing operations, including high-resolution cameras. With three-sided glazing, the cabin provides an expansive view of the entire sawmill, allowing for improved visibility and situational awareness. The strategically placed cameras enable the operator to continuously monitor other critical sawing processes, such as loading and unloading, ensuring efficient workflow and timely interventions. This combination of comfort and technology not only boosts productivity but also enhances safety in the work environment, creating a more effective and pleasant working atmosphere for the operator.

Read more

Roller Conveyor

The roller conveyor, designed for horizontal woodworking lines, features the option to sort workpieces sideways. It performs optimally when aligned with the CZ-1/WZM, which includes a short 1.4-meter belt conveyor for extracting cut elements while the cutting head moves backward on vertical support. The conveyor is equipped with leftward and rightward sorting chains that allow the operator to divert workpieces sideways as needed. This solution significantly boosts work capacity, lightens the workload, and reduces the number of staff required to handle workpieces at the output. Additionally, the conveyor can be adjusted to transport certain workpieces straight ahead, enabling them to be cut on equipment such as a multirip saw.

Read more

RZ/CZ-1 H

The RZ/CZ-1 H high-level loading conveyor is engineered to load logs directly onto the sawmill frame, making it an ideal companion for devices like the CZ-1/ZM, CZ-1/WZM, and CZ-1/Big. Its loading ramp greatly enhances efficiency and streamlines the log handling process. For larger diameter logs, we suggest using a heavy-duty loading ramp equipped with feeding chains integrated into the loading arms.

Read moreHigh-Performance Band Saw Sawmills for Precision and Productivity

Looking for dependable band saw sawmill solutions designed to boost efficiency, accuracy, and return on investment? Our premium selection of sawmill equipment is engineered for small to mid-sized woodworking and timber operations aiming to optimize every cut and maximize log yield.

We proudly recommend WIREX sawmills as a top choice for high-performance and reliable timber processing.

Flexible Sawmill Machinery to Match Your Workflow

We offer a wide range of sawmills in both vertical and horizontal configurations—available as stationary or mobile units. Customize your band saw sawmill with options including:

- Manual or hydraulic log handling

- Various power sources: electric, petrol or diesel engine sawmills

- Stationary or fully portable sawmills

- Various log diameter capacities

- Vast selection of add-on accessories to enhance cutting versatility

Whether you’re producing beams, boards, or custom timber, our modular sawmill machinery adapts seamlessly to your production goals.

Industrial-Scale Sawmill Equipment Also Available

Need to scale up? We also provide automated sawmill equipment lines built for high-volume industrial operations that demand speed, consistency, and scalability.

Why Our Band Saw Sawmills Stand Out

-

Quick installation – Minimal groundwork required

-

Energy-efficient operation – No transformer station needed

-

Fast deployment – Start cutting with minimal delays

-

Superior cut quality – Cleaner, straighter cuts vs. frame sawmills

-

Lower waste, higher yield – Get the most from every log

-

Scalable systems – From standalone sawmills to full production lines

-

Optimized uptime – Features that reduce downtime and labor

Our band saw sawmills are built for long-term performance, easy operation, and high-precision output—making them a reliable choice for any growing timber business.

Financing Your Sawmill Investment

We know that purchasing high-quality sawmill machinery is a significant step. That’s why we’ve partnered with Venture Asset Finance to offer flexible financing solutions tailored to your needs—whether you’re investing in a single band saw sawmill or a complete line of sawmill equipment.

Ready to upgrade your sawmill?

Explore our range of high-performance band saw sawmills and take your timber processing to the next level.

We work with 30 suppliers

How can we help you?

Please contact us if you have any questions about our product range, need assistance with choosing the best solution for you

Tel: +44 (0) 197 825 4472

Tel: +44 (0) 197 825 4472